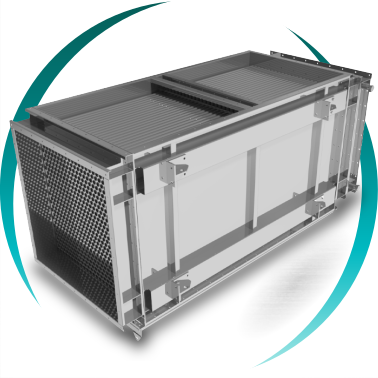

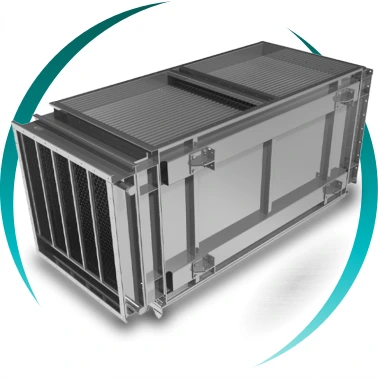

AIR TO AIR HEAT EXCHANGER

BOIXAC air-to-air heat exchangers are industrial systems designed for thermal energy recovery by transferring heat between two completely separate air streams, without any risk of mixing or cross-contamination. These systems capture the energy contained in exhaust or process air to preheat incoming fresh air, significantly improving the overall energy efficiency of the facility.

Thanks to a highly efficient cross-flow configuration, BOIXAC air-to-air heat exchangers can achieve thermal recovery efficiencies of up to 80%, directly reducing energy consumption, lowering CO₂ emissions, and significantly improving the return on investment (ROI) in energy-intensive industrial processes.

Operation and applications principle

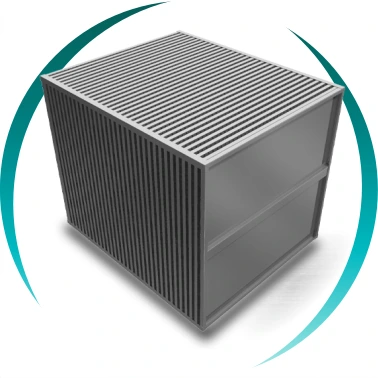

The air-to-air heat exchanger operates using a gas-gas heat transfer system, where two air streams flow through separate channels divided by a heat exchange surface. The hot air transfers part of its energy to the incoming cold air without any direct contact between the streams.

This operating principle allows for:

Recovery of energy from exhaust air, process air, or combustion air

Ensuring high tightness between streams

Stable operation with large air flows

Reduced power requirements in heating or ventilation systems

BOIXAC air-to-air heat exchangers can be easily integrated into existing industrial ventilation lines, dryers, ovens, or air conditioning systems, adapting to the specific requirements of each process.

Key industry advantages

BOIXAC air-to-air heat exchangers are designed for sectors with high energy demands and continuous processes, such as paper, food, chemical, ceramics, metallurgy, and agriculture.

The main benefits include:

Significant energy savings and reduced operating costs

Decreased CO₂ emissions and minimal environmental impact

Improved process efficiency and industrial competitiveness

Optimal integration into industrial control and automation systems

Typical industrial applications

BOIXAC air-to-air heat exchangers are particularly suitable for processes with large air volumes, including:

Food industry: drying, dehydration, and thermal treatment processes

Paper industry: recovering heat from hot air from ovens and dryers

Chemical and pharmaceutical industry: temperature control and recovery of process air energy

Agriculture and greenhouses: improving energy efficiency in HVAC systems

Ceramics, foundries, and metallurgy: optimizing ovens and industrial heating processes

Technical innovation and construction features

Modular and Custom Design

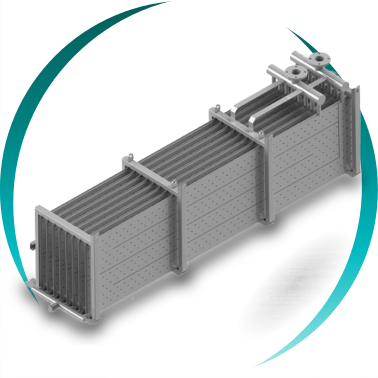

BOIXAC air-to-air heat exchangers feature a modular design with single or multiple cross-flow configurations, allowing dimensions, geometries, and airflow paths to be adapted to each industrial project.

High-Strength Materials

The equipment is designed to operate in demanding industrial environments, with high temperatures and moderate fouling loads, ensuring long-lasting durability and operational stability.

Accessible and Efficient Maintenance

Inspection and cleaning doors facilitate preventive and corrective maintenance, reducing downtime. Optional automatic spray cleaning systems can be integrated.

Energy Efficiency and Sustainability

With thermal recovery efficiencies of up to 80%, these systems provide a high-efficiency solution contributing to lower energy costs and better environmental performance. Typical ROI ranges from 3 to 12 months.

Advanced Tightness

Mechanical sealing systems ensure tightness of up to 99.9%, particularly important in applications with contaminated air, exhaust gases, or large thermal variations.

Typical ROI

3-12 months

Efficiency

up to 80%

Warranty

2 years

Airtightness

up to 99%

Why choose BOIXAC?

BOIXAC provides advanced air-to-air heat exchanger solutions tailored to the industry of the future:

High energy efficiency and reduced overall consumption

Low maintenance costs and reliable operation

Flexible and fully customized design

Compliance with environmental regulations and reduced emissions

Extensive experience in sectors such as metallurgy, industrial minerals, food, energy, pulp, bioplastics, refineries, and advanced industrial processes

What is an air-to-air heat exchanger?

It is an industrial heat exchanger that transfers thermal energy between two completely separate air streams, without mixing, to recover heat and improve energy efficiency.

How does it differ from a gas-to-gas heat exchanger?

The air-to-air exchanger is a specific type of gas-to-gas exchanger, optimized to work with ventilation air, process air, or industrial exhaust air.

Is it suitable for exhaust gases?

Yes. It is particularly suitable for recovering heat from industrial exhaust air, provided the fouling conditions are compatible with the selected design.

What energy efficiency can it achieve?

Depending on process conditions, it can reach thermal recovery efficiencies of up to 80%.

Can it be custom designed?

Yes. BOIXAC designs air-to-air heat exchangers fully customized according to flow rates, temperatures, available space, and process requirements.

What maintenance does it require?

Maintenance is simple thanks to direct access to the heat exchange core and the option to integrate automatic cleaning systems.

What materials are typically used for construction?

Depending on temperature, corrosion, and air or gas type, materials such as carbon steel, stainless steel AISI 304, AISI 316, AISI 309, AISI 310, can be used, ensuring mechanical strength, durability, and compatibility with each industrial application.