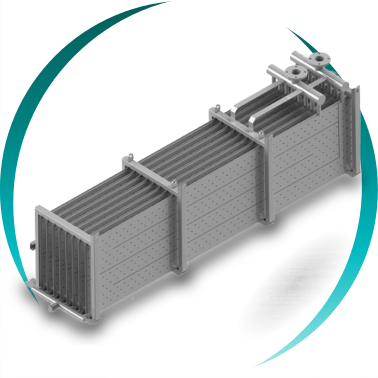

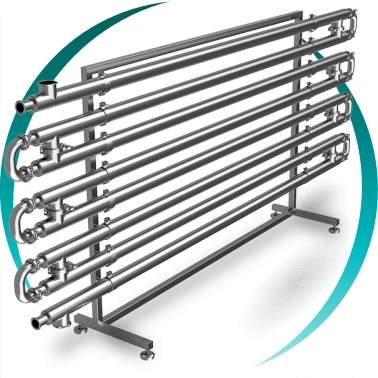

CONCENTRIC TUBE HEAT EXCHANGER

The concentric tube heat exchanger, also known as a double pipe heat exchanger or coaxial heat exchanger, is a robust and efficient thermal solution for heat transfer between two fluids in industrial applications where reliability, strength and ease of maintenance are required.

This type of heat exchanger is characterised by a construction based on concentrically arranged tubes, where one fluid flows through the inner tube and the other through the annular passage formed between the inner and outer tubes. This geometry enables stable, controlled and highly adaptable heat transfer under different operating conditions.

Thanks to accumulated know-how, extensive experience in industrial processes and a continuous commitment to technical improvement, BOIXAC designs concentric tube heat exchangers aimed at optimising thermal performance, reducing operating costs and ensuring a long service life.

Operating principle and heat exchange mechanism

The operation of the concentric tube heat exchanger is based on indirect contact between two fluids at different temperatures, separated by a metallic wall that facilitates heat transfer.

Depending on process requirements, the system can operate in:

- Counter-current flow, where the fluids circulate in opposite directions, maximising the thermal gradient and achieving higher energy efficiency.

- Parallel flow, where the fluids move in the same direction, suitable for applications with specific temperature requirements or thermal stabilisation needs.

This operational flexibility makes coaxial heat exchangers particularly suitable for continuous processes, as well as for evaporation, condensation, cooling or heating of industrial fluids.

Operating principle and heat exchange mechanism

Coaxial heat exchangers can be manufactured with:

- Single circuits, for low or medium thermal power applications.

- Multi-circuit configurations, where several inner tubes operate in parallel within the same assembly, increasing heat exchange capacity without significantly increasing the occupied space.

Their compact and modular design allows easy integration into new or existing installations, as well as adaptation to specific requirements in terms of flow rate, pressure, temperature or fluid type.

Typical ROI

3-12 months

Ideal for

solids, fibres & residues

Warranty

2 years

Design

custom-made

Key advantages of the double pipe heat exchanger

This type of heat exchanger offers clear advantages over other heat exchange technologies:

- High fouling tolerance: large-diameter tubes reduce sediment build-up and minimise the risk of blockages.

- Suitable for fluids containing solids, fibres or residues: particularly recommended when process fluids contain cellulose, fibres, particles or impurities.

- High mechanical strength: suitable for operation under high pressure and temperature conditions.

- Easy maintenance: direct access to the tubes facilitates cleaning and inspection operations.

- Stable and reliable operation: ideal for continuous industrial processes where reliability is critical.

- Optimised energy efficiency: especially in counter-current configurations.

Materials and durability

BOIXAC double pipe heat exchangers are manufactured using materials selected according to the application, ensuring chemical, mechanical and thermal resistance, such as:

- Stainless steel AISI 304

- Stainless steel AISI 316L

- Stainless steel AISI 316Ti

- Stainless steel AISI 321

- Stainless steel AISI 309

- Titanium

- Nickel alloys

This selection of materials ensures a long service life, even under severe operating conditions, and high operational reliability over time.

Industrial applications

Double pipe heat exchangers are a versatile solution for numerous industrial sectors:

- Food and beverage industry: cooling and heating of products containing fibres, pulps or suspended solids.

- Pharmaceutical industry: controlled thermal processes with high hygiene standards.

- Chemical and petrochemical industry: evaporation and condensation of gases, cooling of aggressive fluids.

- Water treatment: handling of fluids containing sediments and impurities.

- Energy and heat recovery: cooling systems and recovery of residual heat.

- HVAC, refrigeration and cold chain: hot and cold water circuits in industrial applications.

Why choose a coaxial tube heat exchanger

When a process requires robustness, ease of maintenance and fouling tolerance, the concentric tube heat exchanger stands out as a highly efficient alternative to other solutions such as plate or conventional tubular heat exchangers.

It is particularly recommended in industrial environments where reliability, process continuity and reduced unplanned downtime are critical factors.