STEAM HEAT EXCHANGER

A steam heat exchanger is a critical component in the thermal management of industrial processes where steam acts as the primary energy carrier. This type of heat exchanger is widely used in sectors such as the paper industry, metallurgy, process chemistry, industrial boilers, drying systems and energy recovery installations.

At BOIXAC, we engineer thermal exchange solutions based on tubular coils with helical fins, continuous fins or plain tubes, designed to operate with steam under demanding pressure and temperature conditions, ensuring efficient, controlled and safe heat transfer in complex industrial environments.

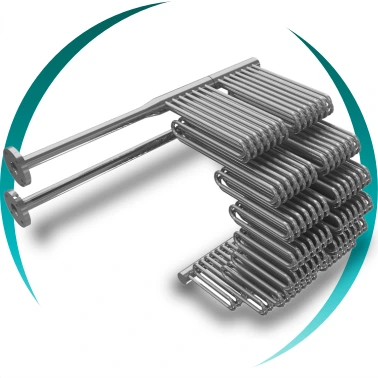

Tubular coils for steam applications

Tubular coils intended for steam heat exchangers are designed to withstand high pressures and extreme temperatures, with operating ranges reaching up to 950 °C, depending on the design and selected materials.

The flexibility in material selection —such as carbon steel, stainless steel AISI 304, AISI 316, duplex, hastelloy or titanium— allows each solution to be adapted to specific process conditions, ensuring high mechanical strength and excellent durability even in corrosive environments, such as marine installations or processes involving aggressive gases.

This approach enables reliable performance with saturated steam, wet steam or superheated steam, maintaining stable operation over time.

Energy recovery and tailor-made solutions

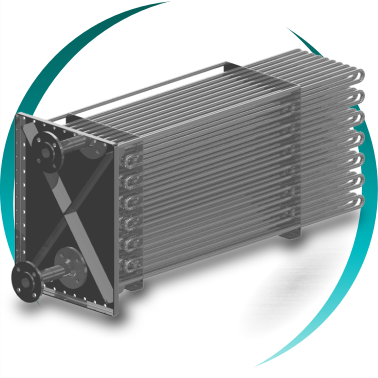

Beyond conventional steam heat exchangers, BOIXAC develops customised thermal exchange solutions focused on energy recovery and optimisation of thermal consumption in industrial processes.

Finned tube heat exchangers are particularly suitable for live steam systems and flash steam energy recovery systems, where the reuse of residual heat plays a key role in improving overall plant efficiency.

Each project is developed based on a detailed analysis of process conditions, flow rates, temperatures, pressures and space constraints, aiming to achieve maximum thermal performance with minimal pressure drop.

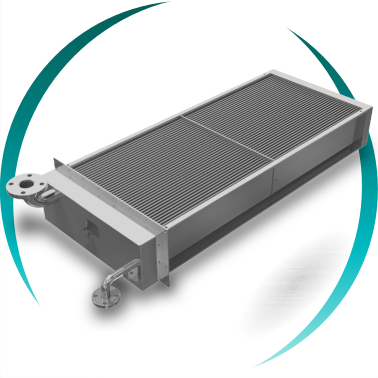

High-pressure steam heat exchanger – HT

The high-pressure steam heat exchanger (HT) is designed for applications requiring the conversion of saturated or wet steam into dry or superheated steam, ensuring optimal steam quality for downstream processes.

With operating capabilities up to 950 °C, this equipment stands out for its structural robustness, thermal stability and operational reliability under extreme conditions.

Typical ROI

3-12 months

Resistance

up to 950ºC

Warranty

2 years

Design

custom-made

What is a steam heat exchanger?

A steam heat exchanger is a thermal exchange device that transfers energy from steam to another fluid or conditions the steam within an industrial process, improving thermal efficiency and process control.

What is a steam heat exchanger used for in industrial processes?

It is used to recover steam energy for heating fluids, drying products, recovering residual heat or improving steam quality, reducing overall energy consumption.

What is the difference between saturated steam, wet steam and superheated steam?

Saturated steam is in equilibrium with water at a given pressure.

Wet steam contains water droplets that reduce efficiency and may cause erosion.

Superheated steam is dry steam heated above the saturation point, suitable for demanding processes.

Which industries use steam heat exchangers?

They are widely used in energy production, chemical processing, pulp and paper, food and beverage, metallurgy, industrial drying, cogeneration and marine installations.

What is the maximum operating temperature of a steam heat exchanger?

Depending on design and materials, a steam heat exchanger can operate at very high temperatures, reaching up to 950 °C in high-demand industrial applications.

What is a high-pressure steam heat exchanger?

It is a unit designed to operate with steam at high pressures, capable of withstanding severe mechanical and thermal loads, used for drying, superheating or energy recovery.

Which materials are commonly used in steam heat exchangers?

Common materials include carbon steel, stainless steel and titanium, selected according to temperature, pressure and corrosive operating conditions.

What is a flash steam energy recovery?

It is the process of recovering energy from steam generated when a hot fluid is suddenly depressurized, allowing this energy to be reused through a suitable heat exchanger.

What is the difference between plain tubes and finned tubes?

Plain tubes are used for direct heat transfer, while finned tubes increase heat transfer surface area and improve efficiency in energy recovery applications.

Can a steam heat exchanger be adapted to limited spaces?

Yes. Through custom coil design and optimized flow configuration, steam heat exchangers can be integrated into confined spaces without compromising thermal performance.