WASTEWATER TREATMENT

Wastewater treatment plants are part of an essential process for sustainable water management and environmental preservation. These processes make it possible to convert wastewater, which has been used in human activities such as domestic, industrial or agricultural use, into clean water to release it into the environment or to reuse it for other purposes.

The water is collected with the sewer until it reaches the wastewater treatment plants (WWTP) which, depending on their capacity, condition the volume and composition of the industrial wastewater they can take on.

This combination of liquids with waste usually has a pH between 6.7 and 7.5 and is composed of suspended, sedimentable and dissolved solids, organic matter, organic nitrogen, ammonium, nitrites and nitrates, as well as organic and inorganic phosphorus.

Sized solutions specially designed for each project.

Accurate forecasts for correct coordination.

Products subject to strict quality controls.

Detailed budgets with precision and rigour.

The purification process makes it possible to reduce and even eliminate the existing pollutants in the water, meeting the growing demand for water and maintaining the recovery and reuse criteria essential for a society that respects and is aware of natural resources.

One of the most common designs consists of a skimmer or degreaser process, followed by primary sedimentation where a tank decants the sediments that have not been previously retained and that in certain cases can be supplemented with chemicals. Then we find the secondary treatment where a biological tank, bioreactor or digester, using microorganisms, accelerates the natural process of elimination of organic matter. Finally we find secondary sedimentation where we observe the characteristic cylindrical tanks of waste water treatment plants where water and biomass have just been separated.

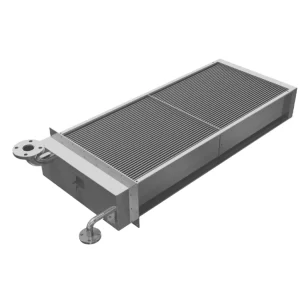

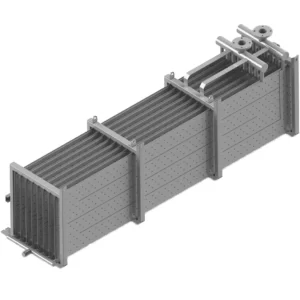

Our heat exchangers are present in the heat treatment and in the chemical transformations of these processes, as well as in the mud and sludge line that thickens, stabilizes and dehydrates them, facilitating their handling and end disposal.