HEAT EXCHANGERS

Industrial heat exchangers enable the transfer of thermal energy between two or more fluids at different temperatures without direct contact. They are key equipment for heating, cooling, condensing, evaporating, or recovering heat within industrial processes, improving energy efficiency and reducing operating costs.

At BOIXAC, we design custom-built heat exchangers, precisely adapted to the real operating conditions of each industrial process across sectors such as food processing, chemical, pharmaceutical, energy, paper, steelmaking, oil & gas (refineries), wastewater treatment, glass, and ceramics, among many others.

This page serves as the canonical guide to BOIXAC industrial heat exchangers, bringing together all available models, typologies, and applications.

What is an industrial heat exchanger?

A heat exchanger is equipment designed to transfer heat from one fluid to another in a controlled and safe manner, optimizing the thermal performance of the process while complying with current industrial regulations and standards.

Main objectives

Energy recovery

Reduction of energy consumption

Process stability

Temperature control

Increased industrial sustainability

How are industrial heat exchangers classified?

There are several engineering-based criteria used to classify heat exchangers.

By type of fluids

Gaseous fluids

Liquid fluids

Solid fluids (granulated or bulk)

High- or low-viscosity fluids

Corrosive or contaminating fluids

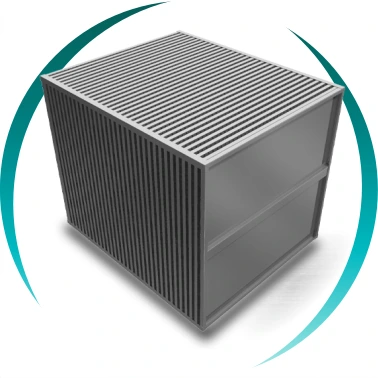

By mechanical construction

Tubular heat exchangers

Plate heat exchangers

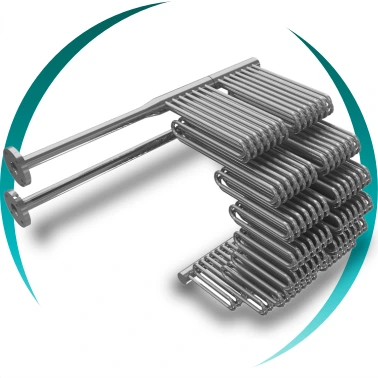

Tube coils

Spiral heat exchangers

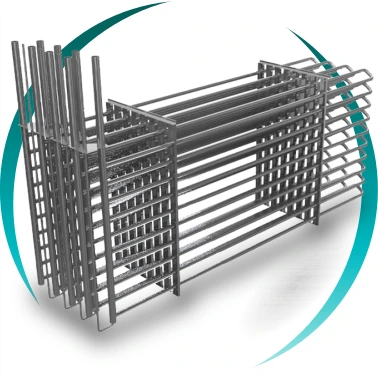

Custom-designed special equipment

By industrial application

Waste heat recovery

Product cooling

Fluid preheating

Condensation and evaporation

HVAC and industrial climate control

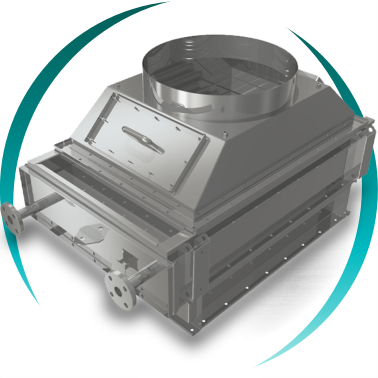

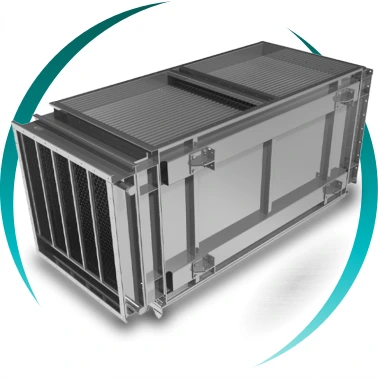

BOIXAC industrial heat exchanger models

At BOIXAC, we structure heat exchangers into technical families, each optimized for specific operating conditions. These families form the core of our industrial heat exchanger cluster.

By operating principle

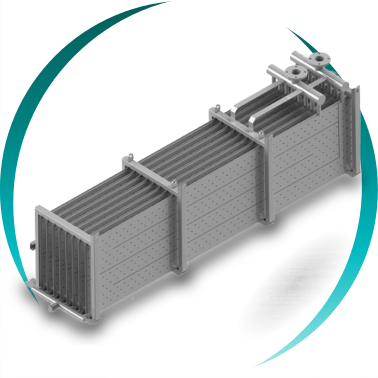

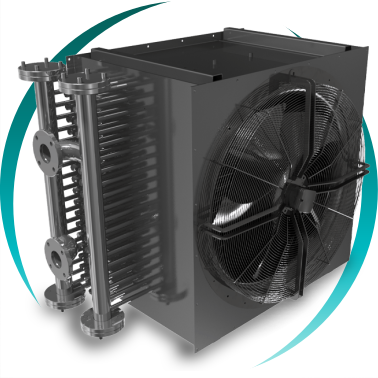

Gas-to-gas heat exchanger

Designed for the treatment of combustion or process gases at high temperature, enabling thermal energy recovery in harsh industrial environments and improving overall system efficiency. Typical applications:

- Combustion flue gases

- Air preheating

- Heat recovery units

- Recuperative thermal oxidizers (RTO)

By construction

Special equipment

How to choose the right heat exchanger model

Selection depends on the type of fluid, temperatures, pressure, process objective, and installation conditions.

Identify fluid types and properties

Define operating temperatures and pressures

Determine the thermal objective of the process

Evaluate available space and maintenance requirements

Select materials and applicable standards (PED, ATEX, hygiene)

Common industrial applications

Heat exchangers are used in applications such as:

Cooling of chemical products

Preheating before reactions

Vapor condensation

Energy recovery

Industrial HVAC

Food and pharmaceutical processes

Custom heat exchanger manufacturing

At BOIXAC, we design tailor-made solutions, optimized for:

Energy efficiency

Durability and reliability

Ease of maintenance

Regulatory compliance

Agility

Service

Strength

Quality

FAQs

What is the best industrial heat exchanger model?

There is no universal model. It depends on the fluid, temperatures, pressure, available space, and process objective.

In industrial environments, the optimal solution is usually a custom-designed heat exchanger.

What types of heat exchangers exist?

Gas-to-liquid, gas-to-gas, liquid-to-liquid, solid-to-liquid, tubular, plate, coil, and special heat exchangers.

This classification allows selecting the most efficient model according to real operating and maintenance conditions.

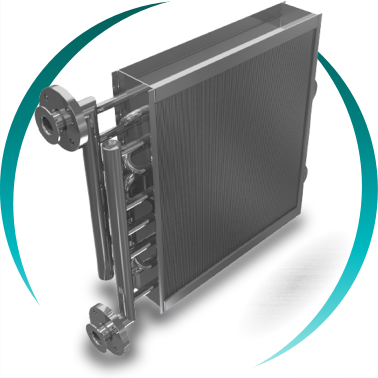

What is the difference between a tubular heat exchanger and a plate heat exchanger?

Tubular heat exchangers better withstand high pressures and temperatures, while plate heat exchangers offer higher efficiency in a smaller footprint.

Tubular heat exchangers are especially suitable for processes with high pressures and temperatures, dirty fluids, or severe conditions. Plate heat exchangers, on the other hand, provide very efficient heat transfer in a compact volume, facilitating maintenance and cleaning in applications with clean fluids.

When is a custom heat exchanger necessary?

When a standard unit does not meet process requirements.

Corrosive fluids, high pressure, strict regulations, or special geometries require customized solutions.

What materials are used in industrial heat exchangers?

Carbon steel, stainless steel, special alloys, and corrosion-resistant materials.

Material selection depends on fluid type, temperature, pressure, and potential corrosion. Stainless steels are common in food and pharmaceutical industries, while special alloys are used in demanding chemical or petrochemical environments.

Which industrial applications use heat exchangers?

Chemical, food, pharmaceutical, HVAC, energy, and general industrial processes.

Heat exchangers are essential for energy recovery, product cooling, fluid preheating, vapor condensation, and industrial climate control systems. Each sector has specific requirements that determine the type of exchanger used.

How does energy efficiency affect heat exchanger selection?

Higher efficiency reduces energy consumption and operating costs.

An efficient heat exchanger improves heat transfer with lower losses, optimizes process performance, and reduces energy impact. In industrial environments, this translates into significant savings and greater sustainability.