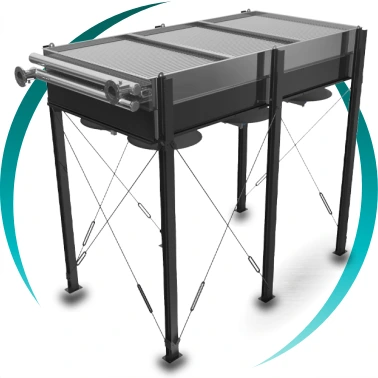

AIR COOLER FOR INDUTRIAL PROCESS COOLING

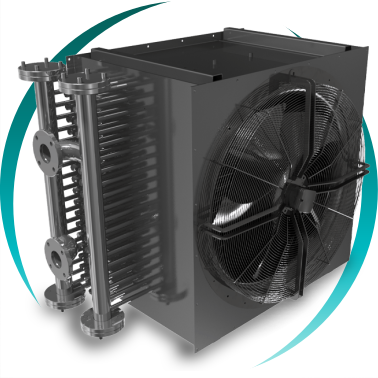

An industrial air cooler is an air-based refrigeration unit that uses an air-to-fluid heat exchanger combined with high-efficiency fans to cool and dehumidify the air in an industrial space or process.

Air cooling equipment with forced ventilation for thermal control and dehumidification

It is designed to maintain controlled environmental conditions in cold rooms, production areas, and spaces where temperature and humidity are critical quality and safety variables.

Thermal function and operating principle

The air cooler operates through:

Air-to-fluid heat exchanger. The refrigerant fluid (direct expansion or secondary circuit) absorbs the thermal load from the air.

Forced ventilation. Industrial fans drive airflow through the coil, ensuring:

Uniform cold distribution

Reduction of thermal gradients

Air velocity controls

Moisture condensation. When the coil surface temperature is below the dew point, controlled dehumidification occurs.

This process enables a stable reduction of both sensible and latent heat loads within the space.

When is an industrial air cooler essential?

It is the appropriate solution when the following are required:

- Precise temperature control (± defined tolerances)

- Simultaneous temperature and humidity management

- Continuous 24/7 operation

- High reliability in aggressive environments

- Uniform air distribution in large volumes

Main industrial applications

- Commercial and industrial cold rooms

- Slaughterhouses and meat processing industries

- Fish and seafood processing and preservation

- Fruit and vegetable storage facilities

- Food handling rooms

- Technified agriculture and greenhouses

- Chemical industry with environmental control

- Drying processes and humidity control

In these sectors, the air cooler is a key element in ensuring product quality, food safety, and process stability.

Difference between air cooler, unit heater, and dry cooler

Equipment |

Main function | Thermal objective |

|---|---|---|

Air cooler |

Cool and dehumidify air | Direct environmental control |

Aerotherm / Heater |

Heat air | Heat supply |

Dry cooler |

Dissipate heat from a fluid to the environment | Indirect circuit cooling |

Technical architecture

Available heat exchangers

- Smooth tubes

- Flat tubes

- Tubes with continuous fins

- Tubes with helical fins

- Pillow or Dimple plates

Selection is based on:

- Thermal load (kW)

- Airflow rate (m³/h)

- Temperature differential (ΔT)

- Relative humidity

- Environmental conditions

Materials and configurations

Fins available in:

- Aluminum

- Copper

- Steel

- Stainless steel

- Titanium

Configurations adaptable to:

- Corrosive environments

- Saline atmospheres

- Processes with frequent cleaning

- Sanitary requirements

Technical advantages of BOIXAC air coolers

Stable environmental control

Consistent maintenance of temperature and humidity.

Custom adaptation

Configuration according to specific project requirements.

Energy efficiency

Optimized aerodynamic and thermal performance.

Continuous operation

Prepared for intensive 24/7 duty cycles.

Structural robustness

Designed for demanding industrial environments.

Engineering criteria for sizing

The design of an industrial air cooler is based on:

- Sensible and latent thermal load

- Required air changes

- Dew point

- Available static pressure

- Pressure losses

- Operating regime (continuous or intermittent)

Correct selection directly impacts:

- Energy consumption

- System service life

- Environmental stability

- Operating cost (OPEX)

Typical ROI

3-12 months

Resistance

to extreme environments

Warranty

2 years

Construction

custom-built

FAQs

What is an industrial air cooler?

It is an air-based refrigeration unit that cools and dehumidifies industrial spaces through heat exchangers and forced ventilation.

It operates by transferring heat from the air to a refrigerant fluid through an exchange coil, while fans ensure uniform and stable air distribution.

How does it differ from a dry cooler?

An air cooler acts on the air; a dry cooler cools a fluid.

The dry cooler dissipates heat from a hydraulic circuit to the environment, whereas the air cooler directly conditions the air within the space.

Does it allow humidity control?

Yes.

When the coil operates below the dew point, controlled condensation occurs, reducing the relative humidity of the environment.

Is it suitable for the food industry?

Yes, especially in cold rooms.

It maintains stable preservation and handling conditions, contributing to food safety and product quality.

Can it be custom-built?

Yes.

The configuration of the coil, fans, materials, and capacity is defined according to thermal load, airflow rate, and specific environmental conditions.

Strategic solution for industrial environmental control

The industrial air cooler is an essential component in refrigeration and environmental control systems where thermal precision and operational reliability are critical.

Within the range of fan-assisted equipment, it represents the specific solution for active space cooling, functionally complementing the unit heater (heating) and the dry cooler (heat dissipation).

In demanding industrial environments, stable control of temperature and humidity is not only an operational requirement but also a critical factor for quality and competitiveness.