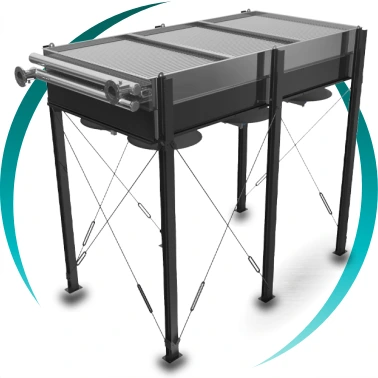

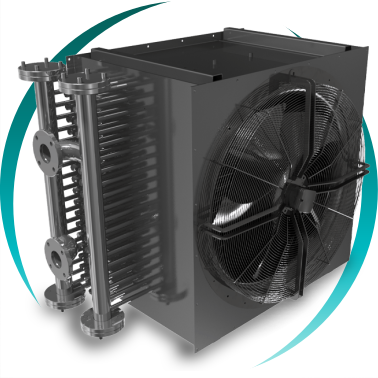

INDUSTRIAL DRY COOLER FOR COOLING PROCESS FLUIDS

An industrial dry cooler is a forced-ventilation heat exchanger designed to dissipate heat from a fluid to the ambient air, without water consumption or evaporation processes.

Fluid heat dissipation system using ambient air

Its main function is to cool process fluids — such as industrial water, water-glycol mixtures, thermal oils, or refrigerants — through dry heat transfer, using outdoor air as the dissipation medium.

It is a widely used solution in industrial refrigeration systems, closed hydraulic circuits, and heat recovery installations.

Technical function: heat dissipation in a closed circuit

The dry cooler typically operates in closed circuits where the hot fluid circulates inside finned tubes. Fans force ambient air through the tube bundle, removing thermal energy to the outside.

This process allows:

- reduction of the process fluid temperature

- stabilization of industrial thermal systems

- protection of sensitive equipment

- optimization of overall energy performance

Unlike evaporative cooling towers, a dry cooler does not require water supply or blowdown management.

Main advantages of BOIXAC dry coolers

Dry cooling (no water consumption)

Eliminates legionella risks and costs associated with water treatment.

Adaptation to continuous industrial operation

Design focused on 24/7 operation.

High operational reliability

Robust operation with reduced maintenance requirements.

Optimized energy efficiency

High-performance fans and thermally optimized configurations.

Free-cooling integration

Possibility of using low ambient temperatures to reduce energy consumption.

Difference between dry cooler, air cooler, and air heater

Equipment |

Main function |

|---|---|

Air heater |

Heats air by supplying thermal energy to the space. |

Air cooler |

Cools and dehumidifies ambient air in industrial spaces. |

Dry cooler |

Dissipates heat from a fluid to the ambient air. It does not act on indoor air. |

Main industrial applications

Dry coolers are essential in sectors where process fluid heat dissipation is required:

Power generation

- power plants

- steam turbines

- diesel and gas engines

Chemical and petrochemical industry

- refineries

- gas processing plants

- reactors and auxiliary circuits

Paper industry and heavy manufacturing

hydraulic circuits

lubrication systems

Industrial refrigeration

remote condensers

support for cooling systems

free-cooling systems

Data centers and thermal processes

heat dissipation from chillers

closed-loop cooling circuits

Advanced thermal design

Each dry cooler is sized based on critical parameters:

- fluid inlet and outlet temperature

- design ambient temperature

- fluid flow rate

- allowable pressure drop

- thermal power to be dissipated

- altitude and environmental conditions

- acoustic requirements

- ATEX classifications if required

This approach ensures precise and reliable thermal performance.

Custom manufacturing for each industrial reality

Dry coolers can be manufactured with:

Heat exchange bundle configuration

smooth tubes

flat tubes

continuous finned tubes

helical finned tubes

pillow plates or dimple plates

Available materials

To adapt to demanding industrial environments, the following materials may be used:

- carbon steel

- stainless steel

- aluminum

- copper

- cupronickel

- titanium

- special alloys

Material selection depends on environmental corrosivity, fluid type, and operating conditions.

Construction options and customization

high-efficiency AC or EC fans

modular or compact configurations

low-noise designs

control and monitoring systems

reinforced structures for marine or corrosive environments

compatibility with explosive atmospheres (ATEX)

Typical ROI

3-12 months

Resistance

to extreme environments

Warranty

2 years

Construction

custom-made

FAQs

When is it recommended to install a dry cooler?

It is recommended when heat must be dissipated from a fluid in a closed circuit using ambient air, without water consumption and with high operational reliability.

A dry cooler is the optimal solution when water, water-glycol mixtures, thermal oils, or other industrial fluids need to be cooled in a closed circuit through dry cooling. It is particularly suitable in environments with water restrictions, strict environmental requirements, or the need for continuous operation. It is ideal for critical industrial processes, energy systems, data centers, and applications where mechanical robustness and low maintenance are decisive factors.

What is the difference between a dry cooler and an evaporative cooling tower?

A dry cooler dissipates heat using ambient air (dry cooling), whereas an evaporative cooling tower cools the fluid through water evaporation.

The main difference lies in the operating principle. A dry cooler uses forced ventilation to transfer heat from the fluid to the air without phase change or water consumption. In contrast, an evaporative cooling tower reduces temperature through partial water evaporation, achieving temperatures close to the wet-bulb temperature but with higher maintenance requirements, water consumption, and risk of bacterial proliferation. The selection depends on the required temperature, water availability, health regulations, and total cost of ownership.

Can free-cooling be integrated into a dry cooler?

Yes. When the ambient temperature is sufficiently low, free-cooling allows the fluid to be cooled without the need for additional refrigeration systems.

Free-cooling takes advantage of favorable ambient conditions to dissipate heat directly through the dry cooler, reducing or eliminating the use of refrigeration compressors. This strategy significantly decreases annual energy consumption, especially in temperate or cold climates. It can be integrated as a standalone system or as support for installations with chillers, improving overall efficiency and reducing CO₂ emissions.

What maintenance does an industrial dry cooler require?

It requires periodic cleaning of the tube bundle, fan inspection, and checking of the hydraulic circuit.

Maintenance of a dry cooler is relatively low compared to evaporative systems. It includes periodic cleaning of the fins to prevent loss of thermal efficiency, inspection of fans (bearings, balancing, and electrical connections), leak testing of the circuit, and verification of valves and sensors. Proper preventive maintenance planning ensures thermal stability, extends service life, and maintains the system’s energy performanc

Is it suitable for corrosive or aggressive environments?

Yes, provided that appropriate materials and coatings are selected according to environmental conditions.

Dry coolers can be manufactured in stainless steel, treated aluminum, copper, cupronickel, or titanium, depending on the level of environmental corrosivity or the nature of the fluid. In marine, chemical, or aggressive atmospheres, it is essential to select suitable alloys and apply protective surface treatments. Proper material specification ensures structural integrity, sustained thermal performance, and long service life.