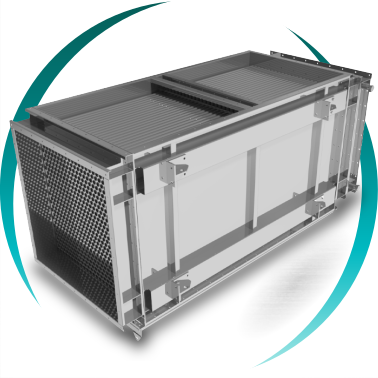

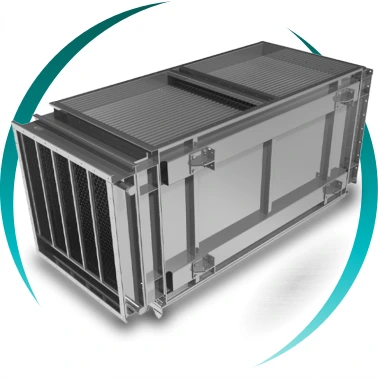

INDUSTRIAL AIR-TO-AIR HEAT EXCHANGER

The air-to-air heat exchanger is an industrial thermal exchanger designed for energy recovery between two separate air streams, using expanded tube technology against end plates, achieving gas tightness of approximately 99%, with excellent tolerance to high temperatures and highly fouled environments.

Thermal energy recovery in industrial processes with high-temperature air and heavy fouling

These units make it possible to recover the energy contained in hot exhaust air or process air to preheat clean supply air, transforming an inevitable energy loss into reusable useful energy, with a direct and measurable impact on:

reduced energy consumption,

lower operating costs,

reduced CO₂ emissions,

and improved overall energy efficiency of the installation.

Technological positioning within the gas heat exchanger cluster

The air-to-air heat exchanger:

Uses expanded tubes (no welding)

Provides high gas tightness (~99%)

Allows fouling and the integration of cleaning systems

Is highly suitable for high-temperature operation

Unlike:

The air-to-flue gas heat exchanger, with welded tubes and 100% gas tightness

The crossflow plate heat recovery unit, which does not tolerate fouling

Optimized crossflow architecture for demanding industrial processes

Thanks to a gas–gas crossflow configuration, designed using advanced thermal and mechanical engineering criteria, BOIXAC air-to-air heat exchangers can achieve thermal recovery efficiencies of up to 80%, positioning them among the best ROI solutions in industrial energy efficiency.

The absence of welding between tubes and plates minimizes mechanical stress, making this technology a particularly robust option for intensive thermal cycles, very high temperatures, and severe operating conditions.

When to choose an air-to-air heat exchanger

The air-to-air heat exchanger is the optimal solution when it is necessary to:

Recover thermal energy between air streams

Operate at high temperatures

Handle high fouling levels

Maintain near-total separation between flows

Ensure long-term mechanical stability

In processes involving polluting combustion gases, absolute 100% tightness requirements, or very strict environmental regulations, it is more appropriate to select an air-to-flue gas heat exchanger with welded tubes.

The correct selection of the heat exchanger mainly depends on:

Gas temperature,

Fouling level,

Safety requirements,

Specific process conditions.

Operation of the air-to-air heat exchanger

Operation is based on a controlled gas–gas thermal exchange, in which two air streams flow through independent channels, separated by an optimized heat transfer surface:

The hot air releases part of its thermal energy

The incoming cold air absorbs this energy

There is no direct contact between air streams

High system tightness is maintained

This principle allows:

Recovery of energy from exhaust air or process air

Stable operation with large air flow rates

Reduction of required power in HVAC systems and industrial processes

Integration into existing installations without interrupting production

Key advantages for industry

BOIXAC air-to-air heat exchangers are designed for continuous, energy-intensive industrial processes, delivering direct benefits:

- Significant energy savings

Reduction in operating costs

Lower CO₂ emissions

Improved overall process performance

Increased industrial competitiveness

Integration with advanced automation and control systems

Typical industrial applications

BOIXAC air-to-air heat exchangers are particularly suitable for:

Food industry: dryers, dehydration, thermal treatments

Pulp and paper industry: heat recovery from hot air in ovens and dryers

Chemical and pharmaceutical industry: process air and thermal control

Agriculture and greenhouses: energy optimization of climate control systems

Ceramics, foundries, and metallurgy: high-temperature processes

Design, innovation and construction features

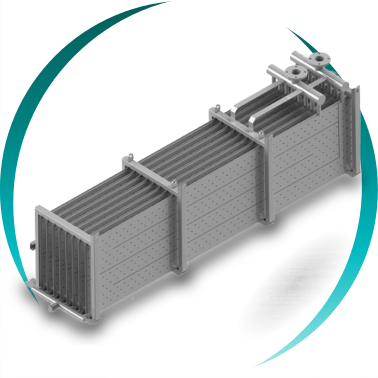

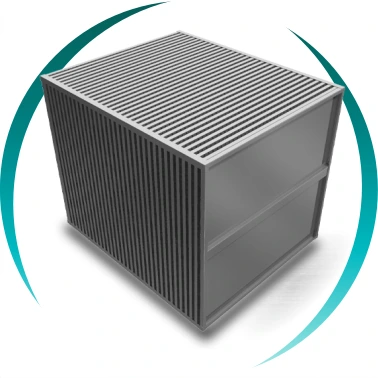

Modular and fully custom design

Single or multiple crossflow configurations, defined using real process data.

Expanded tube technology

Weld-free mechanical joint that reduces thermal and mechanical stress, ideal for high temperatures and demanding environments.

High-resistance materials

Material selection based on temperature, corrosiveness, and expected service life.

Accessible maintenance

Inspection doors, cleaning access points, and automatic spray cleaning options.

Energy efficiency and sustainability

Efficiencies up to 80% and typical ROIs between 3 and 12 months.

Advanced tightness

Mechanical sealing systems that ensure 99%–99.9% tightness.

Typical ROI

3-12 months

Efficiency

up to 80%

Warranty

2 years

Airtightness

up to 99%

FAQs

What is an air-to-air heat exchanger?

It is an industrial heat exchanger that recovers heat between two separate air streams.

It allows thermal energy to be transferred from exhaust or process air to clean supply air, improving energy efficiency without mixing air streams.

How does it differ from an air-to-flue gas heat exchanger?

In terms of technology and tightness.

The air-to-air exchanger uses expanded tubes (≈99% tightness) without welding, whereas the air-to-flue gas exchanger uses welded tubes with 100% gas tightness.

Is it suitable for high temperatures and fouling?

Yes, especially suitable.

The absence of welding minimizes mechanical stress, making it ideal for very high temperatures and highly fouled environments.

What performance can it achieve?

Up to 80%.

Performance depends on temperatures, flow rates, and configuration, but it enables significant energy reductions in industrial applications.

Can it be custom-designed?

Yes, fully.

Each unit is designed according to real process conditions, available space, and operational requirements.

What maintenance is required?

Simple and accessible.

It includes inspection doors and automatic cleaning options, reducing downtime.

What materials are used?

Carbon steel and stainless steels.

AISI 304, 316, 309, and 310, selected according to temperature, corrosion, and gas composition.