AIR-TO-FLUE GAS HEAT EXCHANGER FOR COMBUSTION GASES

Thermal energy recovery for polluting gases and high-demand industrial processes

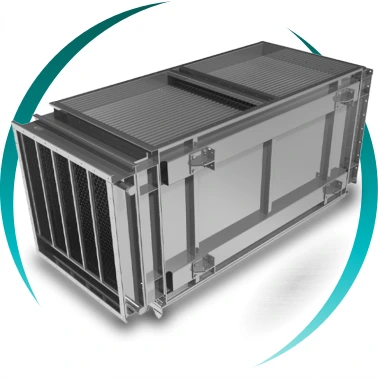

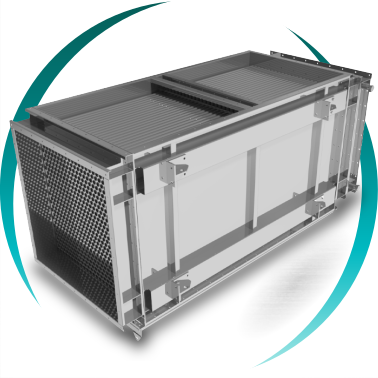

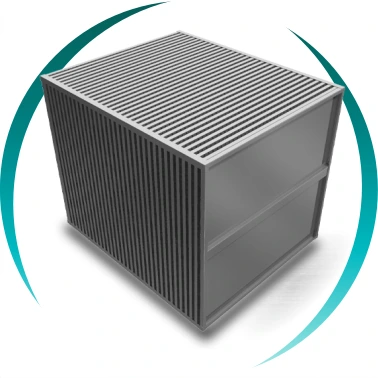

BOIXAC air-to-flue gas heat exchangers are high-performance industrial equipment specifically designed for the energy recovery of extraction gases, process gases, and combustion gases, in environments where absolute 100% gas tightness, resistance to high temperatures, and the ability to operate with polluting and fouled gases are required.

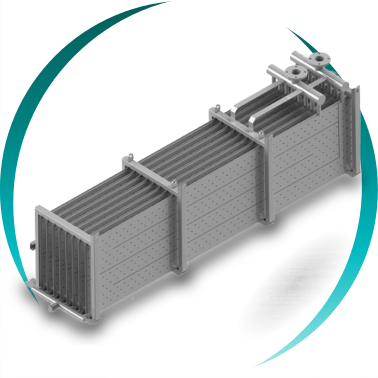

These heat exchangers are part of the BOIXAC gas–gas range and use tube-to-tubesheet welded technology, ensuring a true hermetic separation between gaseous streams, with no risk of cross-contamination, even in critical processes governed by strict environmental regulations.

Technological positioning within the gas heat exchanger cluster

The air-to-flue gas heat exchanger:

Uses welded tubes

Allows fouling and the integration of cleaning systems

Guarantees 100% gas tightness

Is suitable for polluting gases and high temperatures

Unlike the crossflow plate heat recovery unit, which does not tolerate fouling, and the air-to-air heat exchanger with expanded tubes, which offers approximately 99% tightness, but without welding.

Optimized thermal architecture for maximum performance and safety

Through a gas–gas crossflow design, optimized using advanced thermal and mechanical calculation criteria, BOIXAC air-to-flue gas heat exchangers enable energy transfer between two completely separated gaseous streams, maximizing the overall energy efficiency of the process.

The full welding of tubes to the tubesheets eliminates any potential leakage paths, making this type of heat exchanger the reference solution for toxic, corrosive, or particle-laden gases.

With thermal recovery rates of up to 80%, these units:

Reduce process energy consumption

Decrease CO₂ emissions

Accelerate return on investment (ROI)

Directly contribute to industrial decarbonization

Competitive advantages of BOIXAC air-to-gas heat exchangers

BOIXAC air-to-flue gas heat exchangers are designed for industries with high energy demand and severe operating conditions, such as:

Chemical and pharmaceutical industry

Metallurgy, foundries, and steel mills

Ceramic industry

Pulp and paper industry

Food and agro-industrial sector

Energy and industrial combustion processes

Recovering heat from hot gases allows preheating clean air or other gaseous streams, reducing external energy dependency and improving the overall efficiency of the installation.

Key benefits

High energy savings and direct reduction of operating costs

Reduction of CO₂ emissions and improved environmental sustainability

Increased efficiency of the production process

High operational reliability in critical processes

Integration with advanced control systems and Industry 4.0 environments

Industrial applications of air-to-flue gas heat exchangers

BOIXAC air-to-flue gas heat exchangers are ideal for processes involving large gas flow rates, high temperatures, and significant fouling:

Food industry: heat recovery in ovens, dryers, and dehydration processes

Pulp and paper industry: energy recovery from drying and combustion gases

Chemical and pharmaceutical industry: recovery of heat from process gases with precise thermal control

Agriculture and greenhouses: improved efficiency in industrial HVAC systems

Ceramics, metallurgy, and foundries: optimization of furnaces and high-temperature processes

Technical innovation and key features

Modular and fully custom design

Single or multiple crossflow configurations, precisely adapted to each industrial process, flow rate, and temperature.

Welded tube technology

Welded tube-to-tubesheet joints ensure 100% gas tightness between gaseous streams, even when handling polluting gases.

High-resistance materials

Manufactured in stainless steel or carbon steel, depending on temperature, corrosiveness, and gas composition.

Fouling management and maintenance

Option to incorporate:

Strategic inspection doors

Manual cleaning access points

Automatic spray cleaning systems

Typical ROI

3-12 months

Efficiency

up to 80%

Warranty

2 years

Tightness

up to 100%

FAQs

Why choose BOIXAC for an air-to-flue gas heat exchanger?

For safety, efficiency, and industrial experience.

BOIXAC designs high-reliability air-to-flue gas heat exchangers, featuring welded tube technology, tailored to critical processes, with extensive international experience in sectors such as metallurgy, chemicals, energy, refineries, oil & gas, pulp and paper, bioplastics, vegetable oils and fats.

What is an air-to-flue gas heat exchanger?

A gas–gas heat exchanger designed to recover heat from combustion or process gases.

It is an industrial unit that transfers heat between two completely separated gaseous streams, enabling energy recovery without the risk of cross-contamination.

How does it differ from an air-to-air heat exchanger?

In terms of technology and level of gas tightness.

The air-to-flue gas heat exchanger uses welded tubes, achieving 100% gas tightness and allowing the handling of polluting gases. The air-to-air heat exchanger uses expanded tubes, without welding, with approximately 99% tightness.

Is it suitable for polluting or fouled gases?

Yes, absolutely.

Full welding allows operation with polluting, corrosive, or particle-laden gases, with the option to integrate cleaning and maintenance systems.

What performance can be achieved?

Up to 80% thermal recovery.

Performance depends on the process, temperatures, and flow rates, but BOIXAC designs enable the recovery of a very significant portion of the energy contained in hot gases.

What maintenance is required?

Accessible and optimized.

The equipment includes inspection doors, cleaning access points, and automatic cleaning options, minimizing downtime.

Can units be manufactured to measure?

Yes, 100% custom-built.

Each BOIXAC air-to-flue gas heat exchanger is designed according to flow rates, temperatures, available space, and specific process requirements.

What materials are commonly used?

Stainless steel or carbon steel.

Material selection is based on a detailed technical analysis:

AISI 304: non-aggressive gases

AISI 316 / 316L: corrosive environments

AISI 309 / 310: high temperatures

Carbon steel: clean gases and controlled conditions