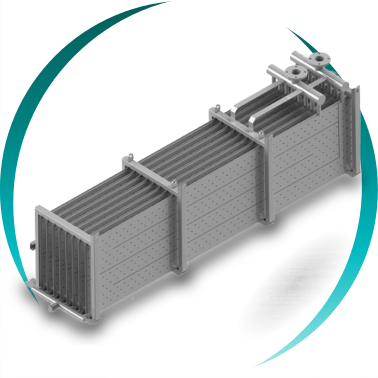

GAS-LIQUID HEAT EXCHANGER

A gas–liquid heat exchanger is an industrial heat exchanger designed to transfer thermal energy between a gaseous fluid (typically combustion gases or process gases) and a liquid fluid, without mixing media and with full control of the heat transfer process.

Industrial heat exchangers for energy recovery and fluid heating

This type of heat exchanger is essential in industrial processes where it is necessary to:

heat service fluids

preheat boiler feedwater

recover energy from combustion gases

reduce overall energy consumption

improve process efficiency and sustainability

Gas–liquid heat exchangers are one of the most efficient solutions for industrial energy recovery, both in new installations and in existing processes.

What a gas–liquid heat exchanger enables

Depending on its design, materials and application, a gas–liquid heat exchanger can operate as:

a hot water or superheated water heat exchanger

a thermal oil heat exchanger

a live steam or flash steam heat exchanger

an industrial boiler economiser

a combustion gas heat recovery exchanger

The objective is to harness the residual energy of hot gases and convert it into useful energy for the production process, reducing the consumption of fuels such as biomass, natural gas, gas oil, diesel, LPG, fuel oil or biogas.

Typical industrial applications

Gas–liquid heat exchangers are used across most industrial sectors with thermal processes:

fire-tube and water-tube industrial boilers

industrial furnaces

cogeneration and trigeneration systems

industrial drying processes

paint booths

industrial kitchens

industrial air handling units (AHUs)

petrochemical, chemical and pharmaceutical processes

food, paper, textile and marine industries

In many cases, the gas–liquid heat exchanger is integrated into equipment such as chillers, heat pumps, dehumidifiers or gas recovery systems, becoming an integral part of the overall process.

Fluid types and real design criteria

The performance and reliability of a gas–liquid heat exchanger depend directly on the type of fluids involved and their actual operating conditions.

Typical liquid fluids

water

river water

glycol water

seawater or saline water

superheated water

condensates

thermal oil (Therminol and similar fluids)

industrial refrigerants

Typical gaseous fluids

combustion gases from industrial boilers

furnace exhaust gases

cogeneration exhaust gases

gases containing dust, ash or solid particles

Factors such as density, viscosity, sedimentation and fouling factor are critical in the design process. In real industrial environments, ignoring these parameters is one of the most common and costly mistakes.

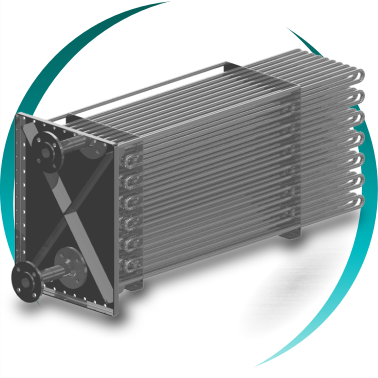

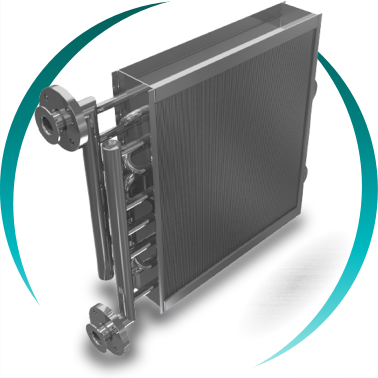

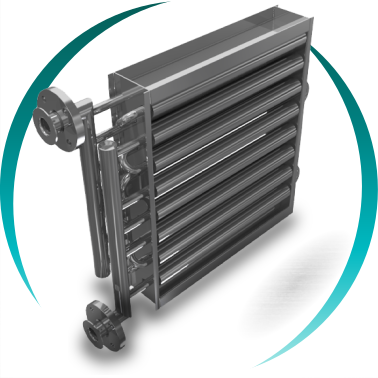

Construction of the heat exchange bundle

Depending on the fouling level, operating temperature and allowable pressure drop, gas–liquid heat exchangers can be built using different configurations:

smooth tubes (without fins)

tubes with continuous fins

tubes with helicoidal (spiral) fins

pillow plate systems

With clean gases, thermal performance can be prioritised.

With dirty gases, ease of cleaning and operational stability are often more important than maximising theoretical heat transfer surface.

Relationship with economisers and heat recovery units

An economiser is a specific application of a gas–liquid heat exchanger, mainly used in industrial boilers to preheat feedwater, increasing boiler efficiency and reducing fuel consumption.

A heat recovery unit is a broader functional concept, aimed at recovering energy from hot gases to heat any thermal fluid within the process.

Both economisers and heat recovery units belong to the same technological family: industrial gas–liquid heat exchangers.

Construction materials and temperature ranges

Material selection is critical to ensure safety, durability and thermal performance:

carbon steel

stainless steel AISI 304, 316, 309, 310

refractory stainless steel

cupronickel

titanium

Depending on design and materials, a gas–liquid heat exchanger can typically operate up to 850 °C and exceed 950 °C in specific industrial applications.

Design focused on maintenance and service life

In real industrial projects, initial performance alone is not sufficient. Long-term behaviour is essential.

For this reason, BOIXAC industrial gas–liquid heat exchangers can incorporate:

accessible inspection openings

heat exchange bundle extraction systems

air-tight sealed structures

fans and auxiliary systems

automatic cleaning and sanitisation systems

anti-corrosion treatments such as Blygold or Heresite

This approach ensures lower energy consumption, high operational availability and sustained savings throughout the equipment’s service life.

When a gas–liquid heat exchanger makes sense (and when it does not)

It is particularly recommended when:

residual gases are available at high temperature

the process operates continuously or semi-continuously

there is a reusable thermal demand

Careful analysis is required when:

allowable pressure drop is very limited

- there is no real use for the recovered heat

Engineering judgement is decisive to avoid inefficient solutions.

Custom industrial gas–liquid heat exchangers – BOIXAC

At BOIXAC we design and conceive custom gas–liquid heat exchangers, adapted to:

the industrial process

the boiler type and burners (single or dual furnace)

the fuel used

the real operating conditions

Our approach combines thermal engineering, industrial experience and design criteria focused on real, measurable and sustained energy savings.

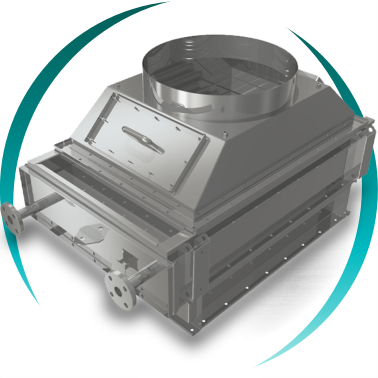

Heat recovery

unit

Industrial

heat exchanger coils

FAQs

What is a gas–liquid heat exchanger?

A heat exchanger that transfers energy between a gas and a liquid.

It enables heat recovery from combustion or process gases to heat fluids such as water, thermal oil or to generate steam, improving industrial energy efficiency.

In which industrial processes is it used?

Boilers, furnaces, cogeneration and drying processes.

In any process with residual hot gases and a reusable thermal demand within the same production system.

Is it the same as a heat recovery unit?

Not exactly.

The gas–liquid heat exchanger defines the type of heat exchange, while the heat recovery unit defines the functional objective of energy recovery.

Can it operate with dirty gases?

Yes, if properly designed.

For gases containing dust or ash, smooth tubes, accessibility and cleaning systems are prioritised to ensure long-term performance.

Which fluids can be heated?

Water, thermal oil and steam.

Also superheated water, condensates, glycol-based fluids and industrial refrigerants.

What temperature can it withstand?

It depends on each project and design.

With specific materials and designs, it can exceed 950 °C.

What energy savings can be achieved?

Significant reductions in fuel consumption.

In many cases, return on investment is achieved within 3 to 12 months.

Can it be installed on an existing boiler?

Yes.

Most gas–liquid heat exchangers are integrated into existing installations through adaptations to stacks and ductwork.