HEAT EXCHANGER COIL FOR INDUSTRIAL THERMAL EXCHANGE

At BOIXAC, we design industrial heat exchange solutions using custom-engineered tube coils, aimed at process cooling, energy recovery, and controlled thermal treatment of gases, liquids, and bulk solids in demanding industrial environments.

Tube coils are not a standard product, but an engineering solution integrated into the process. Each design is tailored to a specific combination of fluid, thermal regime, available space, mechanical conditions, and maintenance requirements, ensuring efficiency, reliability, and optimal service life.

Thermal architecture of tube coils

Tube coils constitute a highly versatile heat exchange architecture, capable of adapting to:

Fluids with very different thermodynamic properties

High temperatures and thermal gradients

Corrosive or abrasive environments

Geometrically constrained spaces

Direct integration into existing process equipment

Unlike standalone standard heat exchangers, a tube coil is usually designed as a functional element integrated within reactors, gas ducts, treatment chambers, tanks, or special heating/cooling systems.

At BOIXAC, the design always starts from the limiting fluid and the actual process, not from a closed typology.

What are tube coils?

Tube coils are heat exchange systems made of tubes arranged in serpentine, coil, or special geometries, optimized to maximize the exchange surface within a given volume, while controlling pressure drop and mechanical behavior.

Their main strength is the ability to adapt to the process, in both steady-state and transient regimes, working with liquids, gases, vapors, or complex fluids.

Types of tube coils we design

The following types are not interchangeable solutions, but technical responses to specific fluids and operating conditions.

Steam heat exchanger

Tube coils specifically engineered for thermal transfer via steam, ensuring controlled, efficient, and stable condensation.

Main features

Design for high temperatures (up to 950°C)

Optimized condensate drainage and thermal shock control

Typical applications

Liquid–liquid exchange

Steam condensation

Heating and cooling of process fluids

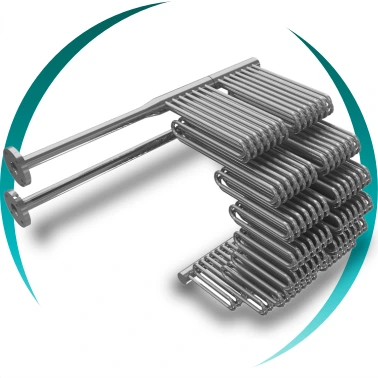

Smooth tube heat exchanger

Smooth tube coils designed for processes with high cleaning, hygiene, and maintenance requirements, with minimal flow resistance.

Main features

Simple and accessible geometry

Easy mechanical cleaning or CIP (Clean-In-Place)

Direct integration into tanks and vessels

Typical applications

Process fluid cooling

Food, chemical, and pharmaceutical industries

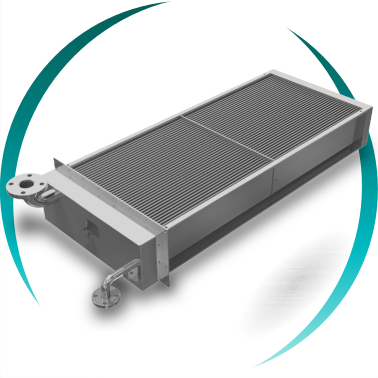

Flat tube heat exchanger

Flat tube coils designed to maximize exchange surface in very limited spaces, with special attention to pressure drop.

Main features

Reduced aerodynamic resistance (lower fan consumption)

Improved overall heat transfer coefficient

Typical applications

Space-constrained processes

Chemical, pharmaceutical, and Oil & Gas industries

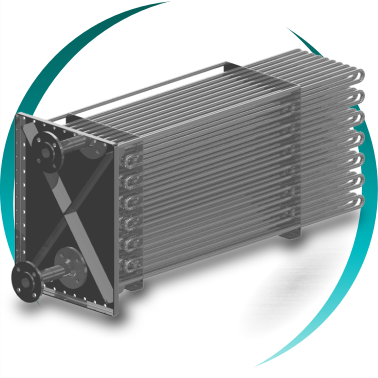

Weldless heat exchanger

Industrial tube coils without welds on the primary circuit, designed for mechanically challenging environments.

Main features

No critical fatigue or corrosion points

High resistance to vibrations and thermal cycles

Demountable design for inspection and maintenance

Typical applications

Boilers

Evaporators and condensers

Critical process equipment

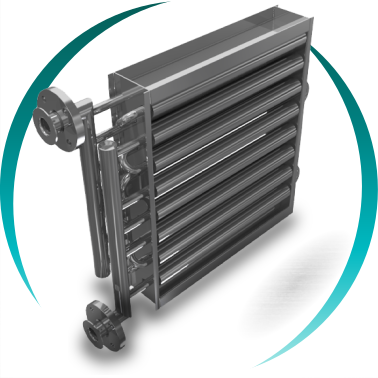

Finned tube heat exchanger

Finned tube coils with helical or continuous fins, especially indicated when the limiting fluid is a gas.

Main features

Significant increase in heat transfer surface

Optimized according to fouling and pressure drop

Ideal for fluids with low heat transfer coefficient

Typical applications

Process cooling and heating

Energy recovery

Food, pharmaceutical, chemical, paper, and Oil & Gas industries

Liquid tube heat exchanger

Thermodynamic solutions to transfer heat between two liquids, which may be viscous, sticky, or even contain sediments.

Main features

Handles viscous, dirty, or sediment-laden fluids

Demountable or fixed designs depending on maintenance requirements

High operational reliability

Typical applications

Wastewater, sludge

Butter, molasses, syrups

Oil, paints, varnishes, coatings

Seamless

heat exchangers

Stainless steel

heat exchangers

FAQs

What are the main applications of tube coils?

Process cooling, energy recovery, and controlled thermal treatment.

BOIXAC tube coils are used for cooling thermal oils, process fluids, steam condensation, waste heat recovery, and gas cooling, as well as in special applications fully integrated into the process.

When is it recommended to use finned tube coils?

When the limiting fluid is a gas.

Fins allow increasing the effective heat transfer surface when the heat transfer coefficient is low. Geometry is defined according to fouling, flow regime, and permissible pressure drop.

What are the advantages of weldless tube coils?

Mechanical reliability and extreme durability.

The absence of welds eliminates critical fatigue and corrosion points, increasing service life in high-pressure, vibration, or aggressive fluid applications.

How is the appropriate material for a tube coil selected?

According to fluid, temperature, and lifecycle.

We evaluate chemical compatibility, pressure, temperature, maintenance, and overall cost, ensuring the best balance between performance and durability.

What are the key factors in designing a tube coil?

Process, fluid, space, and maintenance.

We analyze temperatures, flow rates, fluid properties, pass configuration, and accessibility, resulting in a stable, efficient, and fully integrated solution.