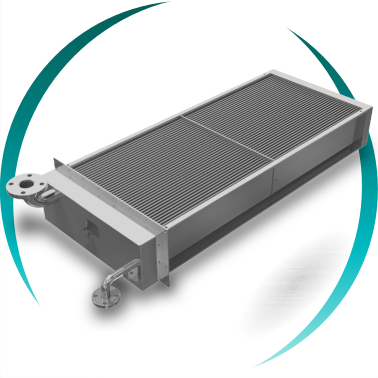

FLAT TUBES HEAT EXCHANGER

The flat tubes heat exchanger is a type of industrial heat exchanger specifically designed to provide a compact, efficient and energy-optimized solution in applications where pressure drop, aerodynamic efficiency and thermal performance are critical factors.

This type of heat exchanger can operate both as a gas-to-gas heat exchanger and as a gas-to-liquid heat exchanger, making it particularly suitable for industrial ventilation systems, energy recovery, process air treatment and applications with high flow rates.

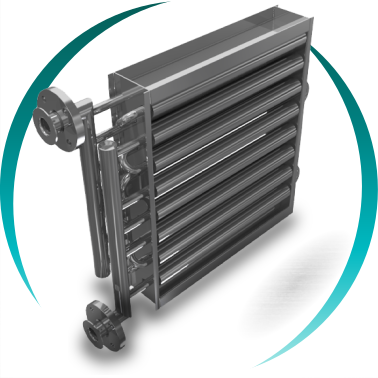

Distinctive features of flat tubes

The main difference between flat tube heat exchangers and conventional round tube heat exchangers lies in their oblong or flattened geometry. This shape significantly reduces the so-called dead zone that forms downstream of round tubes when air flows across them.

In round tubes, this dead zone generates turbulence that increases aerodynamic resistance, raises pressure drop and slightly reduces the heat transfer coefficient. In contrast, flat tubes offer a more aerodynamic profile that:

reduces air flow resistance

minimizes system pressure drop

improves the overall heat transfer coefficient

reduces energy consumption associated with fans or blowers

Flow analysis using thermographic cameras or CFD simulations clearly shows how reducing tube height and adopting a flattened shape enables a more uniform flow distribution and more efficient heat transfer.

Operation and application principle

BOIXAC flat tube heat exchangers are typically designed as tubular coils, where the heat transfer fluid flows inside the flat tubes while the process gas or air flows externally.

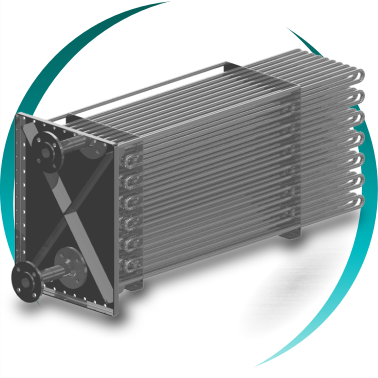

This operating principle makes them particularly suitable for:

heat recovery in industrial ventilation systems

thermal exchange in gas-to-gas processes

gas-to-liquid systems with low pressure drop requirements

installations where available space is limited

The combination of compactness, low pressure losses and good thermal performance makes these units a highly competitive solution for improving the overall efficiency of industrial installations.

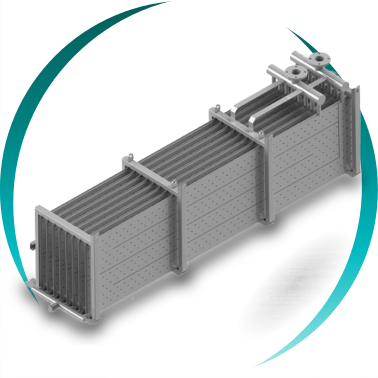

Compact design, cleaning and robustness

Despite their high performance, flat tube heat exchangers maintain a relatively simple and accessible structure, facilitating maintenance and cleaning operations compared to other high thermal density solutions.

BOIXAC designs these units by adapting:

tube geometry

coil arrangement

construction materials

to the specific conditions of each project, ensuring high durability, mechanical stability and operational reliability, even in demanding industrial environments.

Typical ROI

3-12 months

Resistance

high robustness

Warranty

2 years

Design

very compact

What is a flat tube heat exchanger?

It is an industrial heat exchanger that uses flattened, oblong-shaped tubes to improve aerodynamic efficiency, reduce pressure drop and optimize heat transfer.

What is the difference between flat tubes and round tubes?

Flat tubes reduce dead zones and airflow turbulence, lowering aerodynamic resistance and improving thermal performance compared to round tubes.

In which applications is a flat tube heat exchanger recommended?

In gas-to-gas and gas-to-liquid applications, energy recovery, industrial ventilation systems and processes with high flow rates and low pressure drop requirements.

Are flat tube heat exchangers moreenergy efficient?

Yes. Their aerodynamic geometry reduces the energy consumption associated with fans or blowers, improving overall system efficiency.

What level of fouling can they handle?

They are suitable for moderately fouled media. In highly fouling environments, alternative solutions such as smooth tubes may be considered.

Can they be custom-designed?

Yes. Flattened tube coils can be custom-designed to match available space, flow rates and specific process conditions.

What maintenance do they require?

Maintenance is relatively straightforward thanks to their accessible structure and lower fouling accumulation compared to denser solutions.

In which industries are flat tube heat exhangers used?

Energy, oil and gas, food and beverage, agriculture and greenhouses, chemical industry, heavy industry, marine, HVAC, refrigeration, water treatment, transport and marine installations.