SEAMLESS HEAT EXCHANGER

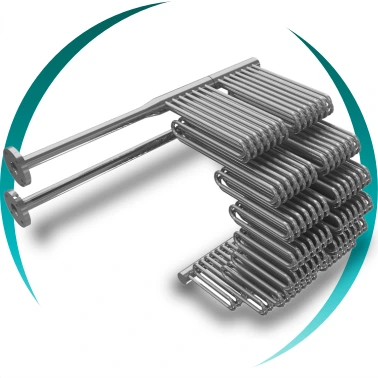

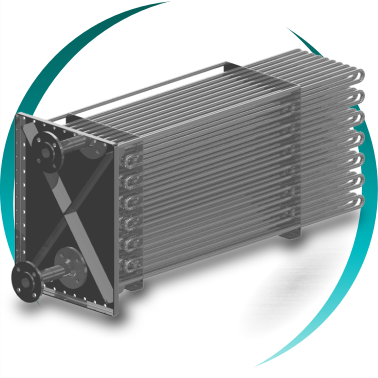

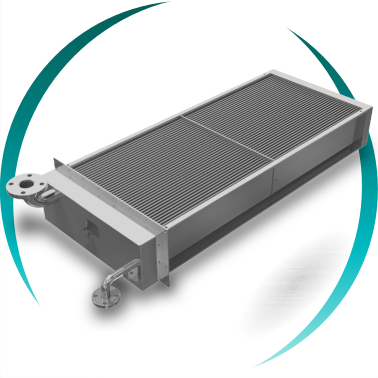

The BOIXAC seamless heat exchangers are industrial units designed for efficient thermal energy recovery and transfer by means of a continuous helical tube coil manufactured without welded joints. This construction concept ensures very high mechanical reliability, facilitates inspection and quality control procedures, and significantly reduces certification requirements in critical industrial applications.

Also known as cartridge-type heat exchangers, these units are particularly suitable for direct integration into other systems such as boilers, evaporators, condensers and industrial process equipment, providing a compact, efficient solution that can be easily installed using a flanged connection.

Their simple yet highly efficient architecture makes them a benchmark solution for high value-added industrial projects, including aerospace, nuclear, chemical and energy applications.

Operating principle and application fundamentals

The seamless heat exchanger operates through a continuous helical tube coil, through which the process fluid flows either internally or externally. The complete absence of welds eliminates critical stress concentration points, improves behaviour under thermal expansion and increases resistance to high pressures.

This construction principle allows:

Highly efficient heat transfer within a reduced footprint

Operation with liquid fluids or vapour

Safe operation at high pressures and temperatures

A significant reduction in leak and structural failure risks

The cartridge format enables direct insertion into existing equipment, allowing vapour condensation, fluid cooling or energy recovery before reinjection into the process circuit.

Key advantages for industry

BOIXAC seamless heat exchangers are designed for demanding industrial environments where reliability, safety and ease of inspection are decisive factors.

Main advantages include:

Complete elimination of welds and structural weak points

Reduced inspection, testing and certification costs

Compact design with high thermal transfer density

Easy installation via flanged connection

Excellent resistance to high pressure and severe process conditions

Typical industrial applications

Thanks to their robustness and versatility, BOIXAC seamless heat exchangers are used in a wide range of industries:

Food and beverage processing: vapour condensation and thermal control

Agriculture and greenhouses: energy recovery and climate control

Chemical and pharmaceutical industry: high-safety process applications

Industrial HVAC and refrigeration

Water treatment and purification

Industrial drying and marine installations

Technical innovation and construction features

Flexible configurations

Helical tube coils can be designed in multiple formats, spiral diameters and tube sections, precisely adapted to each application and process condition.

Seamless construction

Continuous manufacturing without welded joints provides outstanding mechanical strength, even in applications subject to fouling, high pressure or intensive thermal cycling.

Operational precission and reliability

The intentionally simplified yet highly precise design results from specialised technical support and extensive experience in complex industrial projects, ensuring stable operation and long service life.

Typical ROI

3-12 months

Resistance

to high pressures

Warranty

2 years

Design

no welds

Why choose BOIXAC?

BOIXAC concep solucions avançades d’intercanvi de calor orientades a processos industrials crítics:

Alta fiabilitat i seguretat constructiva

Optimització del control i la certificació

Dissenys compactes i integrables

Solucions personalitzades segons procés i sector

Experiència contrastada en indústria química, energètica, alimentària, aeroespacial i de procés avançat

What is a seamless heat exchanger?

It is a heat exchanger based on a continuous tube coil manufactured without welded joints, providing high structural reliability and efficient heat transfer.

Why is eliminating welds advantageous?

Because it removes stress concentration points, reduces leakage risks and simplifies inspection and certification processes.

How does it differ from a conventional heat exchanger?

It stands out for its compact design, high-pressure resistance and ease of integration into existing equipment.

Is it suitable for steam applications?

Yes. It is particularly suitable for steam condensation and high-temperature, high-pressure processes.

Can it be integrated into other equipment?

Yes. The cartridge design allows direct insertion into boilers, condensers and industrial process equipment.

What maintenance does it require?

Maintenance requirements are minimal thanks to the simple construction and the absence of welds.

Which construction materials are commonly used?

Depending on the application, carbon steel and stainless steels AISI 304, AISI 316, AISI 309 and AISI 310 are used.