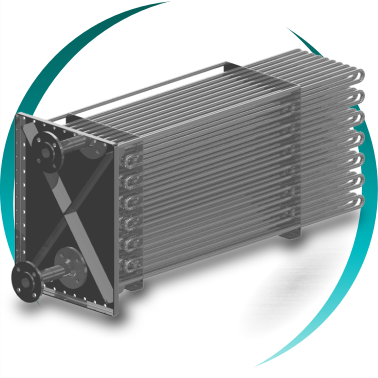

SMOOTH TUBES HEAT EXCHANGER

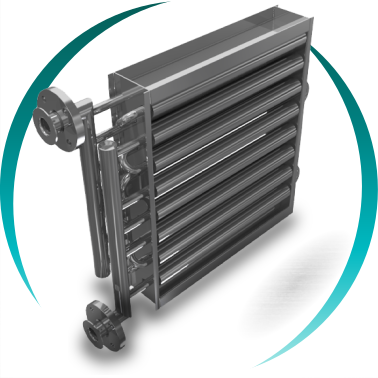

The smooth tube heat exchanger is an industrial heat exchanger design based on bare tubes, without fins, specifically developed for applications with high fouling factors, elevated temperatures, or strict cleaning and hygiene requirements.

This type of heat exchanger is widely used in sectors such as food and beverage, energy, pharmaceutical, paper, chemical and textile industries, as well as in processes involving viscous products or fluids containing sediments, such as dairy products, vegetable oils, margarines, juices, creams, plant-based beverages or animal fat processing.

Operating principle and applications

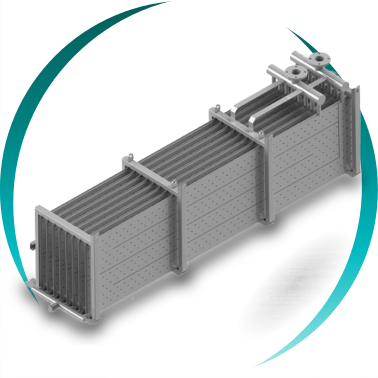

The smooth tube design allows efficient operation as a liquid-gas heat exchanger, even when air streams contain solid particles, fibres, oils or dust, reducing clogging risks and facilitating mechanical or chemical cleaning.

These units are also highly effective as liquid-liquid heat exchangers, particularly when handling viscous, sticky or sediment-laden fluids. They are commonly installed submerged in tanks for dissolution, liquefaction, heating or controlled cooling processes.

Design focused on maintenance and durability

Smooth tube heat exchangers are designed to minimize downtime thanks to easy access to the tubes and the absence of components that could critically accumulate dirt. This makes them a robust and reliable solution for continuous processes or installations with frequent cleaning cycles.

BOIXAC conceives these units using configurable tubular coils, adapting geometry, diameter and layout to the specific operating conditions of each project.

Typical applications

Energy, oil and gas, food and beverage, agriculture and greenhouses, chemical industry, HVAC, refrigeration, heavy industry, marine, wastewater treatment, transport and marine installations.

Typical ROI

3-12 months

Ideal for

high fouling factors

Warranty

2 years

Design

custom-built

What is a bare or smooth tube heat exchanger?

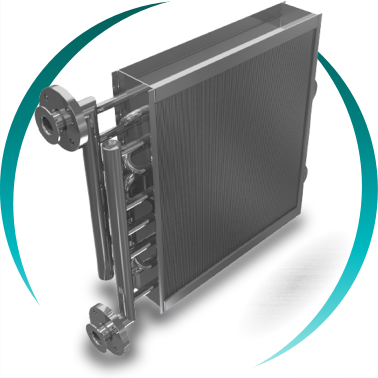

A bare or smooth tube heat exchanger is an industrial heat exchanger made of bare tubes without fins, designed for fluids with high fouling, high viscosity or strict cleaning requirements.

When is a smooth tube heat exchanger recommended?

It is recommended for processes involving viscous fluids, sediments, solid particles or environments where cleaning and hygiene are critical.

What is the difference between smooth tubes and finned tubes?

Smooth tubes facilitate cleaning and reduce fouling, while finned tubes prioritize heat transfer in clean environments. The selection depends on the application.

Can a smooth tube heat exchanger be used for liquid-gas applications?

Yes. It is particularly suitable for liquid-gas duties where air streams contain dust, fibres or oils, minimizing blockages.

What materials are commonly used?

Carbon steel, stainless steel AISI304, AISI316L, hastelloy, duplex and titanium, selected according to temperature, corrosion and fluid characteristics.

Can a smooth tube heat exchanger be custom-designed?

Yes. Tubular coils allow fully customized designs according to space, flow rates and process requirements.

What maintenance is required?

Maintenance is limited thanks to the unfinned design, which simplifies access, cleaning and periodic sanitation.