LIQUID-LIQUID HEAT EXCHANGER

A liquid–liquid heat exchanger is equipment designed to transfer thermal energy between two liquid streams without mixing them. It is one of the most frequent and critical operations in the chemical, pharmaceutical, food, and energy industries, whether for process water cooling, service fluid heating, or energy recovery from hot streams.

The correct choice of technology directly determines energy efficiency, operational reliability, maintenance costs, and the overall service life of the installation. For this reason, selecting a liquid–liquid heat exchanger is not a catalogue exercise, but an engineering decision.

The BOIXAC approach: conceptual criteria before technology

At BOIXAC, we address liquid–liquid heat exchange from a conceptual engineering perspective. Our contribution goes beyond recommending a specific model; we perform an in-depth analysis of the real process parameters:

Operating pressure and temperature

Flow rates and hydraulic regimes

Fluid properties (viscosity, corrosiveness, toxicity)

Fouling tendency or presence of solids

Thermal differentials (ΔT) and transient cycles

Space constraints, maintenance requirements, and future scalability

Based on this analysis, we identify the technological family that offers the best overall balance between performance, robustness, and life-cycle cost. In liquid–liquid applications, this selection usually focuses on four main typologies, each with a clearly defined application domain.

Decision matrix: comparison of key technologies

Optimal selection is based on balancing pressure, thermal efficiency, ease of maintenance, and cost. This table summarizes the engineering criteria we apply to each conceptual design.

Parameter / Requirement |

Removable tubular |

Shell and tubes | Concentric tubes (double pipe) |

Gasketed plates |

|---|---|---|---|---|

Pressure range |

Medium | Very high | Medium | Low |

Thermal efficiency |

Moderate | High | Moderate / High | Very high |

Flexibility and compactness |

Low | Medium | Very high | Very high |

Cleaning and |

Excellent | Complex | Medium | Complex (clean fluids) |

Tolerance to |

Medium | High | High | Limited |

Typical applications |

Very dirty fluids, solids, fouling | Heating /cooling industrial process water | High pressure, circuit isolation | Limited space and clean fluids |

Our conceptual criteria: how we apply the matrix in real cases

The matrix above is a theoretical basis. In practice, industrial processes are often hybrid and require expert judgment. At BOIXAC, the final decision is based on these pillars:

Pressure as the first filter

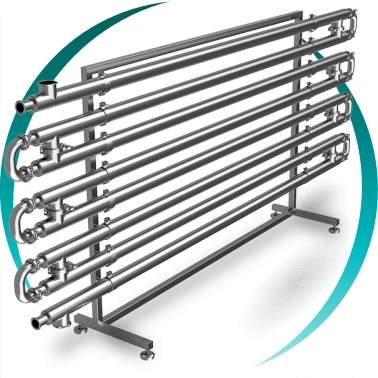

When pressure or thermal differentials are high, we prioritize tubular designs—especially concentric tubes or shell-and-tube—due to their mechanical robustness and tolerance to stress.

Maintenance defines geometry

For fluids with a high fouling tendency (cooling tower water, industrial effluents, food products), removable tubular heat exchangers are often the only viable long-term option, as they allow direct mechanical cleaning.

Space and scalability decide

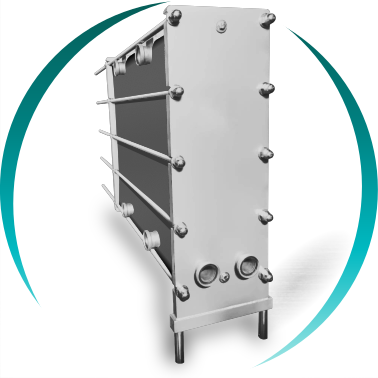

When space is limited or future thermal load growth is expected, the modularity and high compactness of plate heat exchangers can be decisive, provided that pressure and fluid cleanliness conditions allow it.

ΔT and thermal sensitivity refine selection

For very high temperature differentials or severe thermal cycles, the free expansion of tubular designs prevents structural stress and premature failures.

Brine

Steam

Water

Thermal oil

FAQs

Which type of liquid–liquid heat exchanger is most suitable for demanding industrial processes?

Tubular and shell-and-tube heat exchangers are the most suitable for demanding industrial processes due to their robustness and reliability.

In real industrial environments, fluids can vary, operating conditions are not always constant, and long-term maintenance is critical. In this context, tubular designs—both concentric tube and shell-and-tube—offer superior mechanical and thermal tolerance, as well as greater adaptability to changes in flow rate, pressure, or fluid fouling. This robustness makes them the reference solution in most continuous processes.

Which heat exchanger is safest for high-pressure operation?

The tubular heat exchanger is the safest option for high-pressure applications or large thermal differentials.

High-pressure safety depends directly on structural simplicity and the design’s ability to absorb stress. Tubular heat exchangers, especially concentric or double-pipe designs, eliminate critical elements such as gaskets or thin plates, allowing operation at very high pressures and significant ΔT without risk of premature failure. This is why they are common in supercritical processes, hydrotesting, and high-demand industrial circuits.

How does fluid fouling or scaling influence heat exchanger selection?

Dirty or fouling fluids require heat exchangers with direct mechanical access to ensure efficient cleaning.

When a fluid tends to foul or contains suspended solids, cleaning capability determines equipment service life. Tubular and shell-and-tube heat exchangers allow direct mechanical cleaning of the tubes, ensuring stable performance over time. In contrast, closed geometries or narrow channels limit this possibility and increase operating costs, especially in continuous services.

When does it make sense to use a plate-and-gasket heat exchanger?

Plate-and-gasket heat exchangers are suitable when fluids are clean, pressures are moderate, and space is very limited.

Semi-welded plate heat exchangers offer very high thermal efficiency and excellent compactness, but their application range is limited. They perform optimally with clean or slightly dirty fluids and within controlled pressure and temperature ranges. In industrial processes with operational variability, complex fluids, or long-term reliability requirements, tubular or shell-and-tube solutions usually provide a more favorable life-cycle cost.

Which heat exchanger is recommended for large temperature differences (ΔT)?

Tubular heat exchangers are the most suitable for handling large temperature differentials.

Large thermal differentials generate significant expansion that can cause internal stress. Tubular designs allow free expansion of the tubes, reducing structural risks and extending equipment service life. More complex configurations may require special solutions to avoid failures, increasing system complexity and cost.

Which heat exchanger is safest when one fluid is very dirty and the other is critical or clean?

The concentric tube heat exchanger is a very safe solution for separating a dirty fluid from a clean circuit.

In these applications, the priority is protecting the critical fluid. Concentric tubes allow the dirty fluid to circulate through the outer annulus, while the clean fluid flows through the inner tube, simplifying material selection and maintenance on the sensitive side. This configuration is especially valued in desalination, chemical processing, marine applications, and systems with aggressive waters.

How do you choose between a tubular and a shell-and-tube heat exchanger?

Shell-and-tube is ideal for large surface areas; tubular is optimal for very high pressure or extreme cleaning requirements.

When a large heat transfer surface is required with a standardized and scalable solution, shell-and-tube is an excellent option. Conversely, when factors such as very high pressure, difficult fluids, or the need for frequent direct cleaning dominate, tubular designs offer greater simplicity and reliability. The correct choice depends on the relative weight of each variable in the process.

What is the most important factor when selecting a liquid–liquid heat exchanger?

The key factor is compatibility with the process: pressure, temperature, fluids, and maintenance.

There is no universal heat exchanger. Correct selection follows a clear hierarchy: first safety and process compatibility, then long-term operability and maintenance, and finally efficiency and cost. Skipping this order usually leads to chronic inefficiencies, hidden costs, or premature equipment failure.