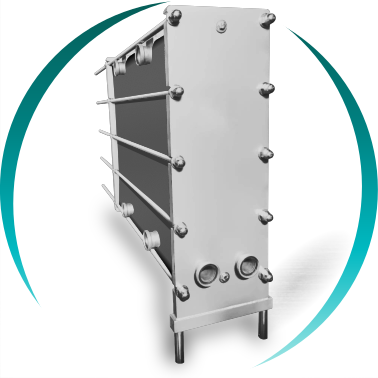

GASKETED PLATE-AND-FRAME HEAT EXCHANGER

A plate and gasket heat exchanger is a compact unit with high thermal efficiency, made up of stacked corrugated plates. It is the optimal solution for heating or cooling clean fluids (water, glycol, pure chemical solutions) where energy savings, space savings, and the ability to easily increase or reduce thermal capacity are a priority.

BOIXAC plate and gasket heat exchangers are industrial units designed for the efficient transfer of thermal energy between two liquid fluids, using a set of removable plates equipped with high-reliability gaskets. This type of heat exchanger enables very intensive heat transfer in a compact volume, with precise process control and high operational flexibility.

The operating principle combines conduction through the plates with forced convection in the channels, generating controlled turbulence that maximizes heat transfer. The fluids flow through alternating channels, very close to each other but completely separated, eliminating any risk of mixing or cross-contamination.

Thanks to their modular design, plate and gasket heat exchangers are a highly versatile solution, especially suitable for industrial processes that require energy efficiency, ease of maintenance, and adaptability to varying operating conditions.

Operation and application principle of plate heat exchangers

The plate and gasket heat exchanger operates by means of a pack of flat corrugated plates, mounted on a frame and sealed by elastomeric gaskets. This assembly defines independent channels through which the hot and cold fluids circulate in counter-current or cross-flow arrangement, depending on the application.

This principle enables:

Highly efficient heat transfer thanks to a high specific heat transfer surface

Complete separation of fluids, even in sensitive processes

Precise adaptation to flow rates, temperatures, and pressure drops

Rapid disassembly of the plate pack for cleaning or inspection

Replacement or expansion of plates as process requirements evolve

BOIXAC plate and gasket heat exchangers integrate easily into existing circuits, both in new installations and in retrofit or energy-efficiency upgrade projects.

Key advantages of industrial plate and gasket heat exchangers

BOIXAC PHEs are designed for demanding industrial environments where operational reliability, energy efficiency, and ease of maintenance are critical factors.

Main benefits:

High thermal transfer density with minimal footprint

Reduced energy consumption and lower operating costs

Full modularity: easy expansion or reconfiguration

Simple maintenance thanks to the removable design

Adaptation to clean or mildly fouling fluids

Ability to operate across wide temperature and pressure ranges

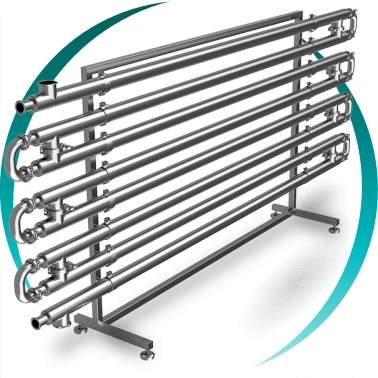

Heat exchangers: choosing between efficiency and robustness

Key parameter |

Gasketed plates | Tubular / Concentric / Shell and tube |

|---|---|---|

Ideal fluid |

Clean, low viscosity, no solids (water, glycol, clean thermal oil) |

Dirty, viscous, particle-laden abrasive |

Thermal efficiency |

Very high (high turbulence in plates) |

Medium-High (application-dependent) |

Compactness |

Excellent (maximum surface in minimum volume) |

Medium / High footprint |

Flexibility |

High (expandable/reducible modules) |

Medium (modular design) |

Maximum |

Limited | High / Very high |

Maximum |

Limited | Very high |

Initial cost |

Competitive (for standard capacities) |

Higher (design and materials) |

Maintenance cost |

Labor-intensive disassembly | Mechanical cleaning (direct or minimal) |

Applications |

Cooling towers, closed circuits, space-critical processes |

Continuous processes with difficult fluids, high pressure, energy recovery, extreme applications |

Typical industrial applications of plate and gasket heat exchangers

BOIXAC plate and gasket heat exchangers are widely used in sectors where thermal control is essential:

Food and beverage industry: pasteurization, product cooling and heating

HVAC and climate control: hot and chilled water production, district heating

Cogeneration and ORC: energy efficiency optimization

Pharmaceutical industry: hygienic processes and closed circuits

Swimming pools and aquatic centers: efficient temperature regulation

Chemical and process industries: heat exchange of technical fluids

Technical innovation and construction features of PHEs

Modular and customized configurations

Plates can be configured with different geometries, corrugation patterns, and number of channels, precisely tailored to each industrial process.

High-resistance materials

Available in AISI 304 stainless steel, AISI 316, titanium, and other special alloys, depending on corrosion, temperature, and fluid type.

High-reliability gaskets

Gaskets ensure excellent sealing performance while allowing quick disassembly for maintenance or cleaning operations.

Energy efficiency

Optimized channel design enables high thermal performance with a fast return on investment in intensive industrial applications.

Insulation

EPP, HVAC, REF

Connections

COSD, COWD, flanges

Structure

wall supports

Delivery

Express, Stock

FAQs

When should a plate and gasket heat exchanger not be selected?

When the fluid contains solids, is highly viscous, or operates at high pressure or high temperature. In such cases, failure will occur.

This technology optimizes efficiency and space, but it has clear mechanical limits. Gaskets and narrow plate passages are vulnerable to:

Irreversible blockage caused by particles

Leakage or failure due to exceeding gasket pressure or temperature limits

As specialists, we advise you on selecting the correct technology. That is why we offer tubular or shell-and-tube solutions in our catalogue for these cases. Choosing plate exchangers in unsuitable environments is the main source of hidden costs due to downtime and spare parts.

Is it true that plate and gasket heat exchangers can be expanded?

Yes, by adding more plates to the same frame.

This is one of their greatest strategic advantages. Imagine your plant’s production increases by 30%. Instead of purchasing a new unit (with new engineering, delivery, and installation costs), BOIXAC can supply an “expansion kit” (additional plates and gaskets), installed in hours rather than weeks.

Direct savings: avoid investing in a new frame, connections, and auxiliary equipment.

Operational agility: adapt system capacity without shutting down the process for days.

It is pure operational savings and flexibility, a key value for growing companies.

What is the approximate price of a plate heat exchanger?

There is no single price; it depends on material, heat transfer surface, and pressure rating. A standard stainless-steel unit can range from a few hundred to several thousand euros, depending on surface area, material, and pressure.

The actual cost is determined after defining flow rate, temperatures, fluids, and pressures. Oversizing can be costly without benefit, while undersizing can be even more expensive. For this reason, BOIXAC provides a free preliminary assessment. Request your no-obligation quotation.

Can the gaskets of a plate heat exchanger be replaced, or must new plates be purchased?

Yes, gaskets can and should be replaced periodically; except in very specific cases, it is not necessary to replace the metal plates.

This is one of their major advantages, and at BOIXAC we provide support so that you can perform these operations independently, with full autonomy.

Can plate heat exchangers be used for seawater or highly corrosive fluids?

Yes, but it is critical to select the correct material (such as titanium for seawater) and an appropriate design.

Absolutely. It is a common but high-risk application. The key is not only the plate material, but the perfect combination:

Plate: Titanium (standard for chlorides), Hastelloy (acids), special alloys

Gasket: compatible material resistant to the same chemical aggressiveness and temperature

At BOIXAC, we have proven experience in aggressive media and advise you in selecting the plate-and-gasket combination that guarantees durability and safety.