PLATES HEAT EXCHANGER

The plate heat exchanger is a family of high-efficiency thermal exchange technologies, recognized for its compact design and excellent use of heat transfer surface area. The common principle is the transfer of heat through metallic plates that separate two fluids without mixing them, achieving very high heat transfer coefficients under controlled conditions.

However, in process engineering, referring to “plate heat exchangers” does not imply a universal solution. This term encompasses fundamentally different designs, each conceived to operate with specific fluid types, clearly defined risk levels, and operational requirements that are not interchangeable across technologies.

This technical cluster exclusively groups the three families of plate heat exchangers that make sense in demanding industrial environments, always within their natural domain of application:

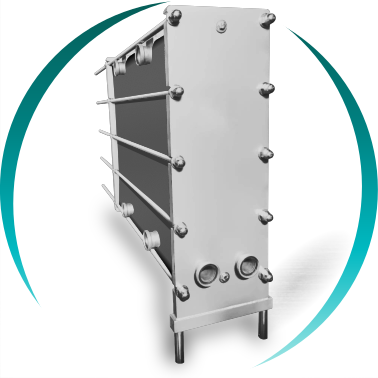

Plate and gasket exchangers (semi-welded)

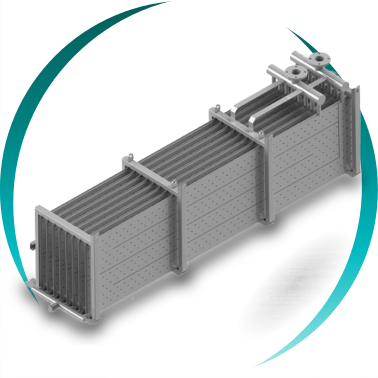

Pillow plate exchangers (double welded wall)

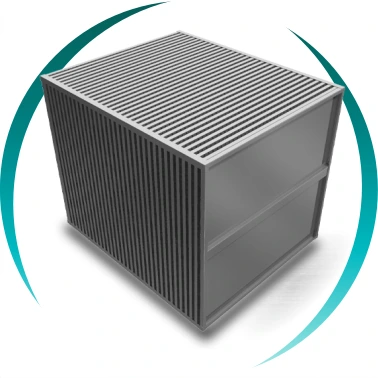

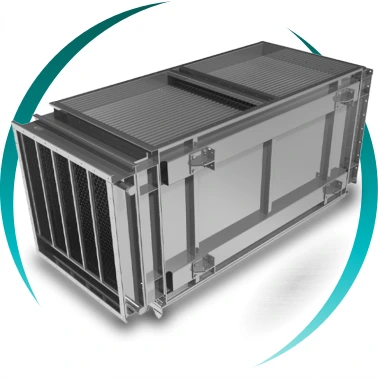

Crossflow heat recuperators

Each of these technologies addresses a different application field and is not interchangeable outside its technical domain.

Plate Heat Exchanger families and their application domains

The table below is not a commercial comparison, but a technical relevance matrix, used during the design phase to validate or discard technologies based on the process, the fluid, and the expected maintenance.

Process

|

Pillow Plate | Crossflow | Plates and Gaskets |

|---|---|---|---|

Construction |

Two sheets spot-welded and inflated | Modules of plates arranged in pure crossflow | Plate packs with perimeter gaskets |

Fluids |

Gas, liquid and bulk solids | Gas (clean) | Liquid (clean) |

Pressure range |

High | Medium | Medium |

Thermal efficiency |

Very high | Very high | Very high |

Cleaning |

Excellent exterior cleaning | No access | Moderate (clean fluids) |

Application |

Drying, material treatment industrial processes |

Industrial processes (clean fluids) |

HVAC, district cooling, food, pharmaceutical |

The BOIXAC Criterion: Why These Technologies Are Not Equivalent

Fluid as the determining factor

In industrial practice, the fluid defines the construction.

Not all fluids can pass through narrow channels, tolerate gaskets, or allow the absence of mechanical cleaning. Ignoring this fact is one of the main causes of premature exchanger failure.

Pillow plates: optimal for viscous, sticky, or sediment-laden fluids, as well as for gases, liquids, and bulk solids.

Crossflow: exclusively intended for clean, stable, and uncontaminated gases.

Plates and gaskets: suitable only for clean liquids, chemically compatible with gaskets, and under controlled maintenance.

Maintenance and service life

A heat exchanger that cannot be cleaned is not viable, no matter how efficient it is on paper. For this reason, when the fluid carries a contamination risk, crossflow and plate-and-gasket exchangers are technically discarded, and the decision shifts to robust solutions such as:

Bulk solids

Viscous fluids

Sticky fluids

Sediments

FAQs

Which plate system best handles dirty fluids or fluids with solids?

Pillow plate heat exchangers.

The design of pillow plates, with smooth relief and inflated channels, allows operation with viscous, sticky, or sediment-laden fluids while minimizing clogging risk. This technology is particularly suitable for drying and treatment processes of gases, liquids, and bulk solids, such as rice, cocoa, or coffee.

Which plate heat exchanger allows future expansion?

Plate and gasket heat exchangers.

Its modular configuration allows adding or removing plates to adapt the heat transfer area to new thermal loads, provided the fluid remains clean and compatible with gaskets. This flexibility makes it valuable for HVAC or stable process installations, though it is not a universal solution.

Why choose a crossflow recuperator?

When working with clean gases and requiring high efficiency in a compact volume.

Crossflow recuperators offer a very compact architecture and high performance in applications with clean and stable gases. However, they do not allow internal cleaning, so any contamination severely compromises viability. For this reason, in severe industrial environments, gas-to-gas tubular solutions are technically safer.