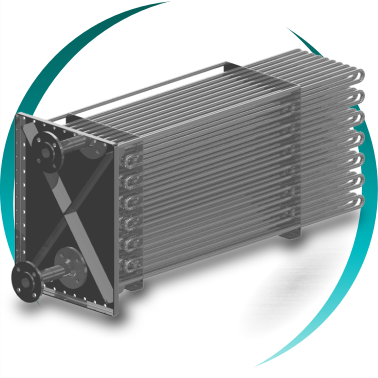

PILLOW HEAT EXCHANGER

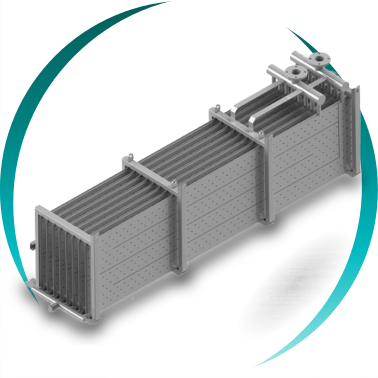

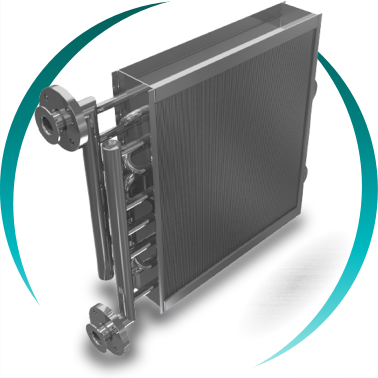

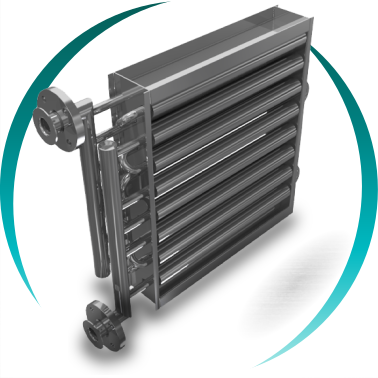

The Pillow Plate heat exchangers by BOIXAC, also known as Dimple Plate heat exchangers, represent an advanced industrial thermal engineering solution that integrates high energy efficiency, mechanical robustness, industrial hygiene and operational versatility, even under extreme process conditions.

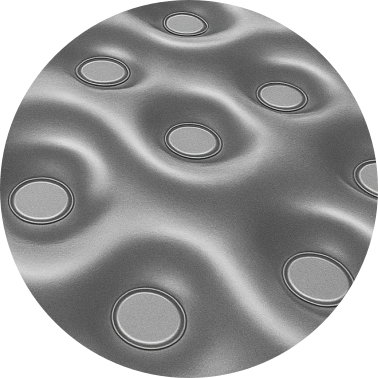

This technology is based on metal plates welded and inflated in a controlled manner, creating a stable and repeatable three-dimensional dimple morphology, specifically designed to maximize the overall heat transfer coefficient (U) in scenarios involving complex flow regimes, fouling fluids or transient operating conditions, commonly found in heavy industry and process engineering.

Unlike conventional plate heat exchangers, the BOIXAC Pillow Heat Exchanger stands out for its geometric and functional adaptability. It can be configured as a flat or curved surface, directly integrated into tanks, applied in outdoor installations, implemented as immersion modules, used as a thermal jacket, or designed as a direct product contact surface. This flexibility allows the equipment to be dimensioned precisely according to pressure, temperature, fluid viscosity and available space, without compromising thermal performance.

Unlike conventional plate solutions, the BOIXAC pillow plate stands out for its adaptability: it can be designed in flat or curved formats, integrated into tanks, installed outdoors, used in immersion modules or as a direct contact surface. This flexibility allows the equipment to be precisely dimensioned according to pressure, temperature, fluid viscosity and available space.

Thermal relief engineering and heat transfer optimization

The internal geometry of BOIXAC Pillow Plates generates controlled turbulence zones that significantly enhance heat transfer, while maintaining a high and stable U coefficient across a wide range of flow rates, temperature differentials and operating conditions.

This behavior is particularly critical in processes such as:

Energy recovery from steam and condensates

Cooling of sensitive food-grade liquids

Thermal treatment of viscous or sediment-laden fluids

Evaporation, concentration and crystallization

High-capacity thermal immersion systems

The optimization of the Pillow Heat Exchanger is based on a combination of advanced thermal calculations, structural stress modeling and flow simulation, ensuring maximum performance with minimal pressure drop. BOIXAC works directly with engineering firms and plant managers to integrate the exchanger precisely at the point in the process where the energy and economic impact is most significant.

Dimple Plate: Structural robustness for high-stress operations

BOIXAC Dimple Plates are engineered to operate reliably under:

High internal and external pressures

Elevated temperatures and aggressive thermal cycles

Fouling media containing sludge, sand, polymers or organic sediments

Mechanical demands typical of heavy industrial environments or marine installations

This structural robustness results in an extended service life, reduced degradation over time and longer maintenance intervals. The fully customized design allows wall thicknesses, inflation patterns and flow orientation to be adapted according to industry standards, safety requirements and real operating conditions.

Industrial hygiene and efficient inspection

The smooth and continuous relief of the dimple geometry minimizes dead zones, residue accumulation and critical contamination points.

BOIXAC Pillow Plates are fully compatible with:

CIP / SIP systems

High-flow cleaning procedures

Direct visual inspection

Configurations with or without external casing

This makes the Pillow Heat Exchanger a reference solution for sanitary applications, where cleanability, traceability and final product quality are critical factors.

Industrial fields where BOIXAC Pillow Heat Exchangers is a benchmark

Food and beverage: cooling of dairy products, beer, wine, juices, ice and immersion-cooled products.

Chemical and pharmaceutical: sensitive fluids, evaporation, isothermal processes and energy recovery.

Energy and petrochemical: thermal recovery from steam, condensates and high-energy residual streams.

Pulp, paper and heavy industry: thermal management of fluids containing solids and sediments.

Marine and naval: robust solutions for corrosive environments and highly variable operating conditions.

Custom Dimple Plate design and optimal process integration

BOIXAC develops each Dimple Plate based on:

Operating conditions (pressure / temperature)

Flow rates and flow regimes

Liquid-liquid, liquid-gas or vapor-liquid interactions

Available space and required orientation

Sanitary and regulatory requirements

Exact customer process specifications

This tailored engineering approach guarantees minimal hydraulic resistance, maximum thermal efficiency and long-term operational stability.

Key competitive advantages

High thermal efficiency through controlled turbulence

Excellent performance with difficult fluids and fouling media

Mechanical robustness and extended service life

Simplified hygiene and inspection

Full dimensional flexibility

Direct reduction of energy consumption and operating costs

Typical ROI

3-12 months

Efficiency

up to 90%

Warranty

2 years

Welds

up to 70% fewer

FAQs

What is a BOIXAC Pillow Heat Exchanger?

A BOIXAC Pillow Heat Exchanger is a heat exchanger composed of two welded and inflated metal plates that create internal channels with high thermal efficiency.

Controlled inflation generates a three-dimensional dimple structure that optimizes heat transfer, enhances mechanical strength and enables operation with complex fluids, high pressures and elevated temperatures, providing superior operational stability compared to other systems.

Why is it more efficient than other heat exchangers?

Because the dimple geometry creates controlled turbulence and reduces dead zones.

This turbulence increases the overall heat transfer coefficient (U), maintains stable performance across wide ranges of flow and temperature, and minimizes pressure drop, even under non-ideal flow conditions.

Can it operate with fouling fluids?

Yes, this is one of its key strengths.

BOIXAC Pillow Plates handle sediments, sand, sludge, polymers and solids-laden fluids thanks to wide channels, continuous relief geometry and easy cleaning, significantly reducing the risk of clogging.

Is the Dimple Plate suitable for energy recovery?

Yes, it is highly efficient for heat recovery.

It is particularly suitable for steam, condensates and hot residual streams, enabling very fast return on investment and actively contributing to the decarbonization of industrial processes.

What is the service life of a BOIXAC Pillow Heat Exchanger?

Very long, even in severe industrial environments.

The structural robustness, material selection and custom design ensure long service intervals, low degradation and reliable long-term operation, depending on the fluid and operating conditions.