TUBES HEAT EXCHANGER

The tube heat exchanger is one of the most widely used technologies in industrial heat transfer due to its robustness, design flexibility, and ability to adapt to multiple fluid combinations. The principle is simple: two fluids exchange thermal energy through the walls of a bundle of tubes, without direct contact.

At BOIXAC, we design tube heat exchangers from a conceptual engineering approach, always starting with a rigorous process analysis: type of fluids, operating regime, temperatures, flow rates, allowable pressure drops, and maintenance requirements.

The fundamental design decision: identifying the limiting fluid

The choice between smooth tubes and finned tubes does not depend solely on whether the fluid is gas or liquid, but on which side limits the overall heat transfer.

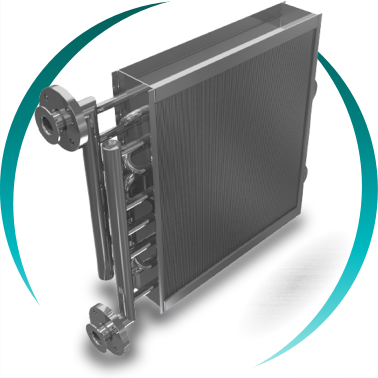

When both fluids have high heat transfer coefficients, as in liquid–liquid or gas–gas exchanges, increasing surface area does not provide significant improvement. In these cases, the optimal solution is a smooth tube exchanger, prioritizing simplicity, ease of cleaning, and durability.

When there is a clear asymmetry between the fluids, usually in gas–liquid processes, one side—normally the gas—acts as the limiting fluid. In this scenario, the use of finned tubes increases the effective surface area on the limiting side, making the exchange technically and energetically feasible.

Finned tubes: selecting the fin geometry

Once the need for fins is defined, the next design decision is the geometry of the fins, which directly affects thermal performance, pressure drop, and durability.

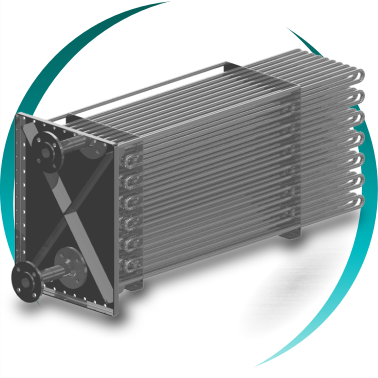

Continuous fin heat exchangers are constructed by placing a set of perforated plates in parallel. A series of tubes passes perpendicularly through the fin pack and is expanded to ensure full contact between tubes and fins. This tube-and-fin construction maximizes thermal efficiency, providing a high overall U factor, and is especially efficient in high-efficiency recuperators where fouling is not limiting.

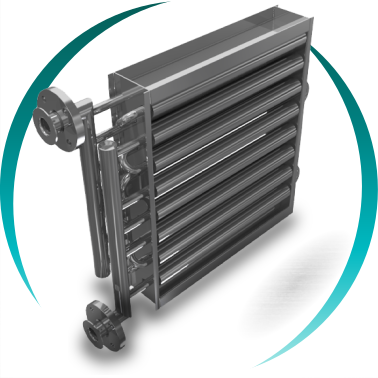

Helical fin heat exchangers consist of independent tubes around which a spiral fin is wrapped. Unlike continuous fins, here the fins are pressed against the tubes, ensuring excellent heat transfer between the materials. Their construction allows thicker fins, providing greater mechanical robustness, making this system optimal for demanding environments: vibrations, corrosion, or high temperatures.

Superheated water

Process fluid

Steam

Thermal oil

FAQs

When does it make sense to use finned tubes?

When one of the fluids limits the heat transfer, usually a gas.

Finned tubes are used when there is a clear asymmetry in heat transfer coefficients between the two sides of the exchanger. In gas–liquid processes, the fins increase the effective surface area on the limiting side and improve overall performance without excessively increasing the equipment volume.

Can finned tubes be used in liquid–liquid exchanges?

No, it is technically inconsistent.

In liquid–liquid exchanges, both fluids have high heat transfer coefficients. In these cases, the dominant resistance is usually the tube wall or fouling, and adding fins does not provide significant benefits, complicating cleaning and maintenance.

How do I know which type of tube heat exchanger is suitable for my process?

It depends on the limiting fluid, temperatures, flow rates, and energy objectives of the process.

The correct selection of a tube heat exchanger requires a comprehensive analysis of the operating regime, the nature of the fluids, inlet and outlet temperatures, allowable pressure drops, and project objectives (efficiency, energy recovery, compactness, or robustness). At BOIXAC, this study allows us to determine from the earliest stage whether the optimal solution is a smooth or finned tube, and which geometry provides the best balance between thermal performance, reliability, and overall system cost.

What advantage does a custom design have over a standard exchanger?

It allows you to maximize thermal performance and reduce operational costs from day one.

A heat exchanger designed specifically for the process takes into account the limiting fluid, actual temperatures, the operating regime, and fouling factors. This prevents oversizing, reduces pressure losses, and ensures stable performance over time. In industrial applications, this initial design is key to achieving the best return on investment.