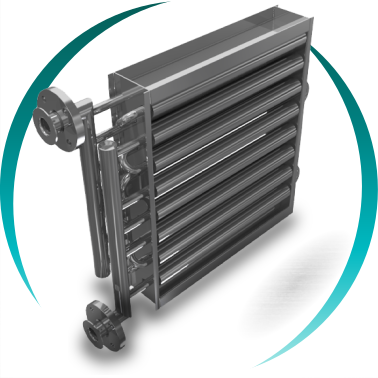

FINNED COIL HEAT EXCHANGER

A finned coil heat exchanger is an industrial thermal equipment designed to significantly increase the heat transfer surface by means of metallic fins attached to the tubes, making it especially efficient in processes involving air or gases and high-temperature fluids.

The finned coil heat exchanger developed by BOIXAC is specifically engineered for high-demand industrial applications where continuous operational reliability, structural mechanical robustness and maximum energy efficiency are absolutely critical. This type of heat exchanger is particularly suitable for operation with live steam, flash steam, thermal oil and superheated water, both in industrial cooling applications and in high-performance energy recovery systems.

It is an ideal solution for industrial installations that require high thermal capacity, continuous operation and long-term operational reliability.

All equipment is subjected to pressure testing and functional verification in accordance with the European Pressure Equipment Directive 2014/68/EU (PED), ensuring regulatory compliance, full documentation traceability and suitability for regulated industrial installations. Additionally, BOIXAC can supply equipment designed in accordance with ASME standards when required by the project or the market.

This regulatory compliance ensures safe integration in regulated industrial environments and critical processes.

Industrial applications of finned coil heat exchangers

The engineering design of these units is intended to withstand severe service conditions, including high pressures and temperatures, intense thermal cycles and variable operating regimes. For this reason, BOIXAC selects high-performance materials such as carbon steel, stainless steel, special alloys or titanium, depending on the nature of the fluid, the corrosivity of the environment, ambient conditions and the specific requirements of the industrial process.

Thanks to this combination of advanced thermal design and mechanical robustness, BOIXAC finned coil heat exchangers are widely used in critical industrial sectors such as food processing, pharmaceutical, pulp and paper, chemical and energy industries, where process continuity, operational safety and plant availability are essential.

They are also particularly suitable for waste heat recovery processes, energy optimization and reduction of the overall thermal consumption of the installation.

Manufacturing of the finned tube bundle

Unlike heat exchangers with continuous fins forming a single rigid block, BOIXAC finned coil heat exchangers incorporate independent helicoidal fins, individually mounted on each tube. This construction solution provides key technical advantages:

Full geometric design freedom, allowing precise adjustment of fin pitch, height, thickness and development according to each application.

Optimized convective heat transfer, especially efficient in air or gas systems.

Improved mechanical behavior under thermal expansion, vibrations and variable load cycles.

Precise adaptation to cleaning, maintenance requirements and aggressive or contaminated environments.

This configuration is particularly recommended for applications with high thermal cycling or variable operating conditions.

The specific thermodynamic and aerodynamic calculations performed by BOIXAC for each project allow the optimal exchanger configuration to be defined, maximizing energy performance and minimizing system pressure losses, both on the fluid side and on the air or gas side.

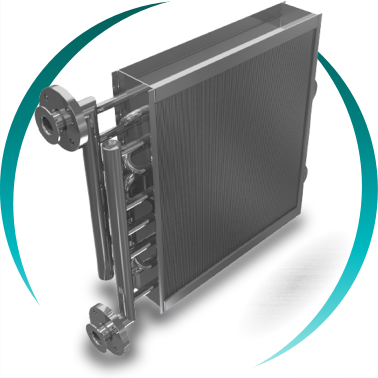

Continuous or helicoidal fins according to the application

Additionally, BOIXAC can also design finned coil heat exchangers with continuous fins, arranged transversely to the tubes, particularly suitable for optimizing heat transfer in very compact installations.

The selection of the fin type is determined through specific thermal calculations based on the actual process requirements.

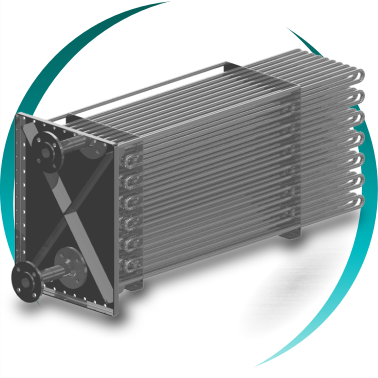

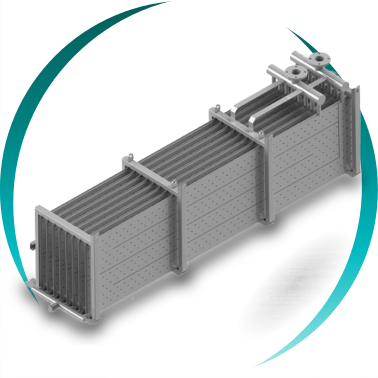

Custom finned heat exchanger manufacturing and configurations

BOIXAC designs custom finned coil heat exchangers, adapting geometry, materials and overall configuration to the specific conditions of each industrial process. Solutions may include:

Plain tubes, tubes with continuous fins or tubes with independent helicoidal fins.

Designs with or without structural frames, depending on mechanical and installation requirements.

Specific air-side sealing to optimize performance and prevent bypass.

Weld-free configurations in critical areas when required for reliability or regulatory compliance.

This flexibility allows the equipment to be precisely adapted to the customer’s real operating conditions.

Complete solutions for industrial installations

BOIXAC finned coil heat exchangers can be supplied with various connection types, such as threaded connections, flanges or plain tubes for direct welding, facilitating integration into both new and existing installations.

In addition, BOIXAC can develop complete solutions integrating auxiliary components such as:

Fans

Droplet separators

Humidification systems

Electric defrost heaters

Pressurized casings

This integrated approach reduces installation time, operational risks and overall project costs.

Typical ROI

3-12 months

Efficiency

up to 90%

Warranty

2 years

Welds

up to 70% less

FAQs

What information is required for a heat exchanger quotation?

To prepare a rigorous quotation, it is necessary to have the main process data, flow rates, temperatures, and space constraints.

For a precise technical and commercial proposal, BOIXAC performs specific thermodynamic calculations. For a water battery, condenser, evaporator, or steam battery, it is required to confirm at least 5 of the following parameters as well as the maximum available dimensions:

To size the water exchanger coil we need you to confirm 5 of the following values as well as the maximum available dimensions.

- Calorific capacity (kcal/h or kW)

- Air flow (m3/h)

- Air inlet temperature (ºC) and relative humidity (%)*

- Air outlet temperature (ºC) and relative humidity (%)

- Water flow (l/h or l/min.)

- Water inlet temperature (ºC)*

- Water outlet temperature (ºC)

- Maximum available sizes (length x height x depth)

To size the condenser we will need you to confirm 5 of the following values as well as the maximum available dimensions.

- Calorific capacity (kcal/h or kW)

- Air flow (m3/h)*

- Air inlet temperature (ºC)*

- Air outlet temperature (ºC)

- Refrigerant*

- Condensation temperature (ºC)*

- Maximum available sizes (length x height x depth)

To size the evaporator we will need you to confirm 5 of the following values as well as the maximum available dimensions.

- Calorific capacity (kcal/h or kW)

- Air flow (m3/h) *

- Air inlet temperature (ºC) and relative humidity (%)

- Air outlet temperature (ºC) and relative humidity (%)

- Refrigerant *

- Evaporation temperature (ºC) *

- Maximum available dimensions (length x height x depth)

To size the steam battery we will need you to confirm 4 of the following values as well as the maximum available dimensions.

- Calorific capacity (kcal/h or kW)

- Air flow (m3/h)

- Air inlet temperature (ºC)

- Air outlet temperature (ºC)

- Steam pressure (Kg/cm2 atm. or bar)*

- Maximum available dimensions (length x height x depth)

What is a finned tube heat exchanger?

A finned coil heat exchanger is a device designed to increase the thermal exchange surface by adding fins to the tubes.

A finned coil heat exchanger is an industrial thermal unit that significantly increases the effective exchange surface by fins mounted on the tubes, improving heat transfer between an internal fluid and an external medium, usually air or gases.

What is the difference between independent helical fins and continuous fins?

Independent helical fins offer greater flexibility and better mechanical performance.

Independent helical fins are mounted individually on each tube, while the continuous fin forms a single finned block. Independent fins allow for greater geometric flexibility, better absorption of thermal expansion, and improved response in environments with high fouling factors.

What applications are best suited for tubes with helical fins?

Ideal for steam, thermal oil, superheated water, and energy recovery.

They are particularly suitable for live steam, flash steam, thermal oil, and superheated water, as well as energy recovery and industrial cooling processes with air or gases, even in the presence of certain fouling factors.

Can finned coil heat exchangers be adapted for each project?

Yes, each heat exchanger is specifically designed for its application.

Each finned coil heat exchanger is fully customized, adapting tube geometry, fin type, materials, and overall configuration according to real process conditions and client requirements.

Do BOIXAC finned coil heat exchangers comply with European regulations?

Yes, they comply with PED 2014/68/EU and can also be manufactured according to ASME standards.

BOIXAC finned heat exchangers are verified and tested in accordance with the European Pressure Equipment Directive 2014/68/EU, ensuring full regulatory compliance. Additionally, BOIXAC can supply units under ASME standards when required by the project.