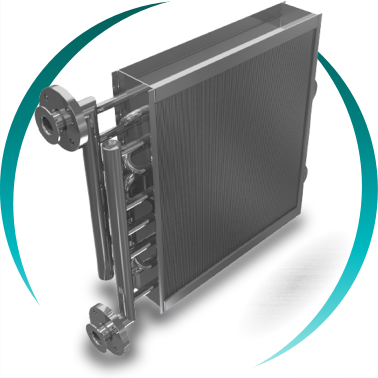

FINS AND TUBES HEAT EXCHANGER

A fins and tubes heat exchanger with continuous fins is an air–fluid heat exchanger designed to maximize thermal transfer efficiency when air or gas is the primary limiting factor of the process.

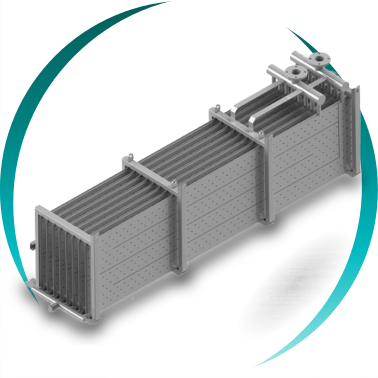

The BOIXAC continuous fins and tubes heat exchanger is specifically engineered for high-efficiency industrial processes where it is essential to maximize the heat transfer surface on the air or gas side while ensuring continuous operational reliability, mechanical and structural stability, and a compact, optimized design.

This type of heat exchanger operates with high thermal conductivity fluids such as water, water-glycol mixtures, steam, thermal oil, and diathermic fluids. It is particularly suitable for applications where air or gas limits overall performance, including industrial HVAC, cooling systems, air and gas treatment, and energy recovery systems.

The continuous fins integrally bonded to the tubes significantly increase the heat transfer surface area on the air side—typically the thermal bottleneck of the system—thereby increasing the overall heat transfer coefficient (U). This allows for reduced equipment size, weight, energy consumption, and total installation cost, without compromising performance or long-term reliability.

Industrial manufacturing and regulatory compliance

The mechanical tube-to-fin expansion manufacturing process ensures optimal, permanent, and uniform thermal contact, guaranteeing high thermal efficiency, structural stability, and consistent long-term performance, even under continuous operation in demanding industrial environments.

All BOIXAC fins and tubes heat exchangers comply with the European Pressure Equipment Directive 2014/68/EU (PED) and can be manufactured in accordance with ASME standards when required by the project, market, or client. This ensures operational safety, full documentation traceability, regulatory compliance, and international acceptance.

Advanced design of fins and tubes heat exchangers

At BOIXAC, we develop fully customized fins and tubes heat exchangers, designed using advanced thermal calculations, realistic industrial maintenance criteria, and material selections aligned with actual process conditions.

Each design aims to achieve the optimal balance between thermal performance, pressure drop, durability, ease of cleaning, and equipment lifespan, maximizing the client’s return on investment (ROI).

Key design decisions for fins and tubes heat exchangers

Tube selection

Tube diameter, wall thickness, and material are defined according to operating pressure, chemical compatibility, and corrosion risk.

Common materials: carbon steel, stainless steel AISI 304 / AISI 316, copper, copper-nickel, and titanium.

Fin material and fin pitch

Available materials: aluminum, Al5754, pre-coated aluminum, hydrophilic or hydrophobic aluminum, galvanized steel, stainless steel, copper, or titanium.

Fin pitch is optimized based on expected fouling, condensation, freezing risk, and cleaning strategy.

Tube bundle geometry

Staggered arrangement: higher turbulence and superior heat transfer coefficient (U).

In-line or square arrangement: lower pressure drop, improved accessibility, and easier maintenance.

Headers and fluid boxes

Sized according to fluid type, flow rate, operating pressure, and thermal cycling conditions.

Protective coatings and surface treatments

Internationally recognized industrial coatings such as Blygold, Heresite, Electrofin, or Aqua Aero, particularly suitable for aggressive or corrosive environments.

Tube bundle configuration and fin pattern

The tube layout and fin pattern directly affect thermal performance, pressure drop, cleanability, and equipment service life.

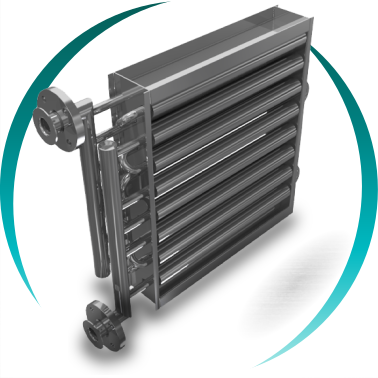

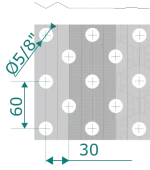

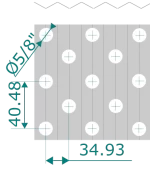

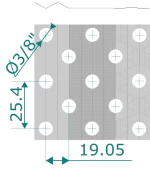

Staggered tube arrangement

Increases turbulence and heat transfer per unit surface area. Recommended for high thermal demand processes, accepting a higher pressure drop.

| Tubes Material | Cu, Cu,Ni, Fe, AISI 304, AISI 316, Titanium |

|---|

| Fins Material | Al, AlMg2.5m, AlEpoxy, AlHy, Cu, AISI 304, AISI 316 |

| Observations | Fins pitch from 1.6 to 6.0 mm and fins thickness from 0.11 to 0.23 mm |

| Tubes Material | Cu, CuNi, Fe, AISI 304, AISI 316, Titanium |

|---|

| Fins Material | Al, AlMg2.5m, AlEpoxy, AlHy, Cu, AISI 304, AISI 316 |

| Observations | Fins pitch from 1.6 to 6.0 mm and fins thickness from 0.11 to 0.23 mm |

| Tubes Material | Cu, CuNi |

|---|

| Fins Material | Al, AlMg2.5m, Epoxy, Cu, AISI 304, AISI 316 |

| Observations | Fins pitch from 1.6 to 6.0 mm and fins thickness from 0.11 to 0.23 mm |

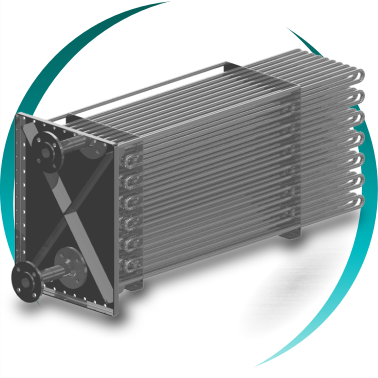

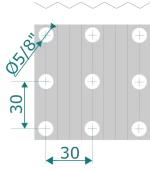

Inline / grid / square tube arrangement

Reduces pressure drop and facilitates cleaning. Recommended for environments with moderate dust levels or high maintenance requirements.

| Tubes Material | Cu, CuNi |

|---|

| Fins Material | Al, AlMg2.5m, AlEpoxy, AlHy, Cu, AISI 304, AISI 316 |

| Observations | Fins pitch from 1.6 to 8.0 mm and fins thickness from 0.11 to 0.23 mm |

Typical ROI

3-12 months

Efficiency

up to 90%

Warranty

2 years

Welding

up to 70% less

FAQs

What is a fins and tubes heat exchanger?

A fins and tubes heat exchanger is an air–fluid heat exchanger that uses continuous fins to maximize thermal transfer when air is the limiting factor.

In industrial applications, it increases the overall heat transfer coefficient, reduces equipment size, and improves energy efficiency in air- or gas-based processes.

What is the difference between continuous fins and helical fins?

Continuous fins maximize heat transfer surface area, while helical fins maximize mechanical robustness.

Continuous fins are optimal for clean, compact environments. Helical fins perform better in dusty conditions or where frequent cleaning is required, preventing performance degradation.

Which applications are best suited for continuous fins?

Industrial HVAC, cooling systems, air treatment, and energy recovery applications.

Especially suitable when air or gas limits heat exchange performance and available space is critical.

When are continuous fins recommended – and when are they not?

They are recommended when air limits heat transfer and maximum efficiency per unit volume is required.

They are not recommended in cases of severe fouling, abrasive particles, or aggressive cleaning, where helical fins, bare tubes, or pillow plate technology are preferable.

What data is required to select a finned coil?

At least five key parameters and the maximum available dimensions must be provided.

To size the water exchanger coil we need you to confirm 5 of the following values as well as the maximum available dimensions.

– Calorific capacity (kcal/h or kW)

– Air flow (m3/h)

– Air inlet temperature (ºC) and relative humidity (%)*

– Air outlet temperature (ºC) and relative humidity (%)

– Water flow (l/h or l/min.)

– Water inlet temperature (ºC)*

– Water outlet temperature (ºC)

– Maximum available sizes (length x height x depth)

To size the condenser we will need you to confirm 5 of the following values as well as the maximum available dimensions.

– Calorific capacity (kcal/h or kW)

– Air flow (m3/h)*

– Air inlet temperature (ºC)*

– Air outlet temperature (ºC)

– Refrigerant*

– Condensation temperature (ºC)*

– Maximum available sizes (length x height x depth)

To size the evaporator we will need you to confirm 5 of the following values as well as the maximum available dimensions.

– Calorific capacity (kcal/h or kW)

– Air flow (m3/h) *

– Air inlet temperature (ºC) and relative humidity (%)

– Air outlet temperature (ºC) and relative humidity (%)

– Refrigerant *

– Evaporation temperature (ºC) *

– Maximum available dimensions (length x height x depth)

To size the steam battery we will need you to confirm 4 of the following values as well as the maximum available dimensions.

– Calorific capacity (kcal/h or kW)

– Air flow (m3/h)

– Air inlet temperature (ºC)

– Air outlet temperature (ºC)

– Steam pressure (Kg/cm2 atm. or bar)*

– Maximum available dimensions (length x height x depth)

What is a diathermic fluid?

A diathermic fluid is a thermal fluid that allows heat transfer at high temperatures without high operating pressures.

It is used in closed industrial circuits, reactors, furnaces, and continuous processes, providing thermal stability and operational safety. Examples include mineral thermal oils, synthetic oils, silicone fluids, and specialized high-temperature fluids.

Why choose BOIXAC for your fins and tubes heat exchangers?

Because we design each heat exchanger specifically for your process.

We combine advanced thermal calculations, high-quality materials, and proven experience in critical industrial sectors, ensuring efficiency, reliability, and measurable results.