DRINK

The beverage and drink industry covers a wide range of products including soft drinks, juices, bottled water, plant-based drinks, energy drinks, milk or alcoholic beverages such as wine, beer, cider or spirits.

Since these are such different products, their production processes diverge greatly, but they all have in common the fact of preserving a flavor, texture and quality that sets them apart, as well as the need for packaging that characterizes them such as cans, glass, ceramic or plastic.

In addition, obviously, to the own regulations and standards in the field of food safety to guarantee its quality when presented on the market.

Sized solutions specially designed for each project.

Accurate forecasts for correct coordination.

Products subject to strict quality controls.

Complete service, we include transport to your factory.

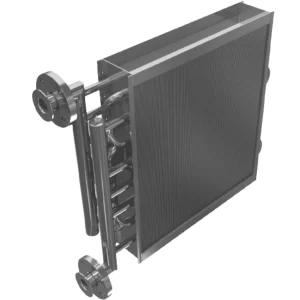

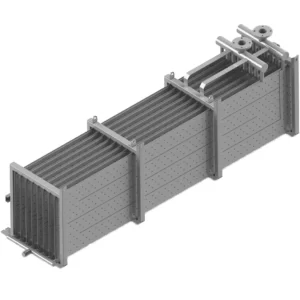

Heat exchangers are necessary in multiple stages of the production processes. These stages differ depending on the product, but we can highlight the mixing and dissolution of ingredients such as syrups and sugars where temperature control speeds up the manufacturing process, the pasteurization and sterilization of certain drinks such as dairy products, carbonation to add bubbles to carbonated beverages or alcoholic and/or malolactic fermentation of beverages such as wine or beer.