PHARMACEUTICAL

The pharmaceutical industry researches, develops, produces and markets drugs and medicines for health and well-being; from oral solids to vaccines. For this reason, when talking about this sector, it is also necessary to mention laboratories, clean rooms and the strict hygiene controls required to avoid biosecurity risks.

Its manufacturing processes include multiple variants depending on the type of product and may involve stages such as chemical synthesis, packaging and labeling.

One of its characteristics is the continuous innovation that involves investments in R&D in addition to the optimization of processes and technologies.

Sized solutions specially designed for each project.

Accurate forecasts for correct coordination.

Products subject to strict quality controls.

Complete service, we include transport to your factory.

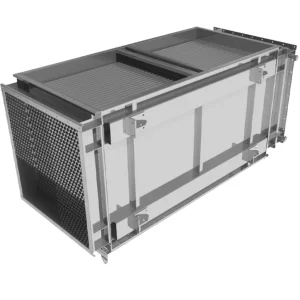

The production process of the pharmaceutical industry comprises multiple areas where temperature control is essential to guarantee product quality and efficacy. In this sense, we can find heat exchangers in processes such as fermentation of biological products, drying to remove or reduce moisture, condensation and evaporation to separate components or purify the product, as well as refrigeration to maximize life useful of the products.

As always it is important to emphasize that each industry has its singularities and, for example, in the case of plasma we find characteristic processes such as the spraying of dry plasma or fractionation which, in addition to changing the alkalinity and alcohol concentration , the change in temperature allows different proteins to group together.