PROCESS AND DRYING

The materials process and drying such as wood, paper, cellulose, cement, lime or glass, involves several stages among which we can find heat treatment and drying of the materials. This is an essential part because it gives them the desired properties and increases their durability.

Drying becomes an essential factor in other areas such as food with cereals, pasta, meat, fish or vegetables, as well as in the tanning of leather and the treatment of fabrics by textile factories and laundries.

Beyond the process itself, certain industries such as metallurgy, mining, glass, talk, dolomite or calcium carbonate can emit a high degree of dust and fumes, which makes it particularly important to implement heat recuperators reusing energy and becoming more responsible with the environment and with society.

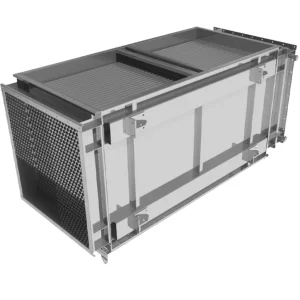

Sized solutions specially designed for each project.

Accurate forecasts for correct coordination.

Products subject to strict quality controls.

Complete service, we include transport to your factory.

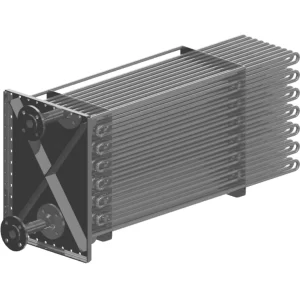

Heat exchangers are of critical importance in all these areas of material processing. For example, in the manufacture of glass we work with the heat recovery from the extraction gases generated during the fusion of raw materials such as silica sand, soda and other components that are melted inside a furnace that works at temperatures of up to 1600ºC. The liquid glass is molded and cooled until the desired result is obtained. The temperature control makes it possible to reduce breakages as well as control the quality of the final product and reduce energy expenditure.

We can find similar cases in other industries such as for example in the paper industry where we provide live steam, flash steam and condensate heat exchangers, among others. The drying process allows water to be removed from plant fibers and wood, optimizing the physical properties of the resulting paper as well as achieving a more efficient and sustainable production.

We can also find heat exchangers in the wood transformation process where drying is essential to reduce moisture and control excess water that could cause deformation and deterioration of the final product. Drying ovens with air recirculation to obtain uniform air treatment are common, and here heat exchangers are an essential product.