SUGAR

Sugar is a crucial commodity in the global economy as it is one of the most widely used sweeteners worldwide by the food and beverage industry such as soft drinks, confectionery, chocolate, preserves and other processed foods.

It is produced mainly from sugar cane and sugar beet, through a crushing and grinding process that extracts the juice and a subsequent purification and crystallization process that allows the final product to be obtained.

In addition, bagasse can be used as boiler fuel for the generation of steam that drives steam turbines in mills.

Sized solutions specially designed for each project.

Detailed budgets with precision and rigour.

Products subject to strict quality controls.

Complete service, we include transport to your factory.

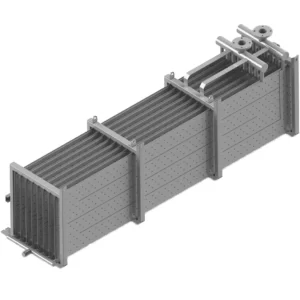

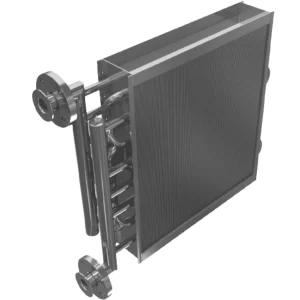

Heat exchangers are key equipment for the sugar industry as, after crystallization, they allow the sugar to be concentrated by evaporating the water. Later, the resulting water vapor is cooled and condensed to be reused in the production process. In other words, the heat exchangers allow optimal management of energy and water, contributing to the efficiency and sustainability of the industrial process.

Heat recovery units and industrial economizers also improve the energy efficiency of industrial boilers that drive turbines by preheating the air. The requirement of using bagasse as a fuel source requires a special design where Boixac Tech is a specialist.