TEXTILE

The textile industry includes a wide range of fabrics produced from natural fibers such as cotton, bamboo, wool or silk, or from synthetic fibers developed by the petrochemical industry such as polyester, nylon or acetate.

In a general way, the manufacturing process consists of preparing the fibers by opening them and cleaning them to later be mixed and homogenized in silos or mixing chambers. The next step is carding which allows the fibers to be separated for subsequent spinning.

In certain factories there may be other intermediate steps such as handing, wicking, combing, yarn dyeing, bleaching or fizzing.

Finally, it is woven using flat looms to obtain fabrics in the plain or openwork and on circular looms for knitted fabrics.

Sized solutions specially designed for each project.

Accurate forecasts for correct coordination.

Products subject to strict quality controls.

Complete service, we include transport to your factory.

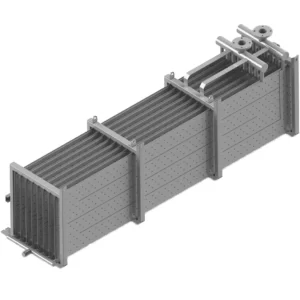

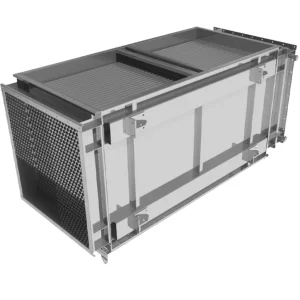

Superheated water, thermal oil or steam heat exchangers are important in different stages of the textile manufacturing process such as fixing the colors, washing or dyeing since, with the correct thermodynamic control, the results are optimized. Further than that, we also implement heat recovery units and economizers in the industrial boilers.